ROI Case File No.237 | 'The Sustainable Strategy of a Nordic Furniture Manufacturer'

📅 2025-10-05 23:00

🕒 Reading time: 14 min

🏷️ LEAN

- Chapter 1: Between Craftsman Pride and Efficiency—The Burden Called Tradition

- Chapter 2: LEAN Brings Streamlining—Conflict Between Efficiency and Craftsmanship

- Chapter 3: Challenge to Protect Customer Experience—Separation of Value and Waste

- Chapter 4: Improvement Never Ends—Sustainable Craftsmanship Evolution

- Chapter 5: The Detective's LEAN Diagnosis—Sustainable Efficiency

- Chapter 6: Beautiful Fusion of Tradition and Efficiency—Evolution of Craftsman Spirit

- Detective's Perspective—Coexistence of Tradition and Innovation

- Related files

Chapter 1: Between Craftsman Pride and Efficiency—The Burden Called Tradition

The week after resolving the Neural Dynamics environment-adaptive OODA case, a consultation arrived from Northern Europe regarding a serious issue facing a traditional manufacturing industry. The seventh case in Volume 18, "Reconstruction of Logic and Verification," concerned a company struggling to balance craftsmanship with efficiency.

"Detective, we're a furniture manufacturer with 150 years of history in Northern Europe, but we're suffering from the inability to maintain traditional craftsmanship while achieving modern efficiency. Our quality is top-notch, but we're losing cost competitiveness."

Lars Andersen, Chief Operating Officer of Nordic Craft Furniture, visited 221B Baker Street with a complex expression. In his hands were outstanding quality evaluation data and, in stark contrast, a report of deteriorating profitability.

"We're an established company manufacturing high-end furniture across Northern Europe. Our craftsmen's skills are world-class, but we cannot adapt to the wave of modern efficiency."

Nordic Craft Furniture's Traditional Strengths: - Established: 1875 (150 years of history and tradition) - Craftsmanship: 45 master-level craftsmen, 120 skill successors - Quality evaluation: 20 consecutive years winning international furniture quality awards - Customer satisfaction: 4.9/5 (absolute trust in top-tier quality) - Brand value: Worldwide recognition as representative of Nordic furniture

The numbers certainly demonstrated traditional strengths. However, Lars's expression was etched with deep crisis awareness.

"The problem is that while our craftsmanship and quality are undoubtedly world-class, manufacturing costs are 40-60% higher than competitors, and we're rapidly losing market competitiveness. We cannot balance tradition and efficiency."

Disconnect Between Traditional Strengths and Modern Challenges: - Product quality: Industry highest (traditional craftsmanship) - Manufacturing cost: +55% vs competitors (lack of efficiency) - Production period: Average 4 months (competitors 6 weeks) - Price competitiveness: Price pressure even in luxury market - Market share: 15% → 8% (halved in 7 years)

"We continue to make 'the highest quality,' but it's no longer 'sustainable business.'"

Chapter 2: LEAN Brings Streamlining—Conflict Between Efficiency and Craftsmanship

"Mr. Lars, what kinds of problems are occurring in your current manufacturing process?"

Holmes inquired quietly.

Lars began explaining the workshop situation with a perplexed expression.

"We value the handcraft-centered manufacturing methods cultivated over 150 years, but this completely conflicts with modern efficiency demands."

Nordic Craft's Traditional Manufacturing Process:

Wood Processing Stage (Craftsmanship Emphasis): - Wood selection: Craftsmen manually select each piece (2 days/product) - Wood drying: Natural drying for 2 years of maturation - Manual processing: All precision processing by hand - Quality inspection: Perfectionist inspection by craftsmen's eyes and hands

Assembly Stage (Individual Response): - Custom response: 100% accommodation of customer requests - Manual assembly: All adhesion, assembly, adjustment by hand - Unlimited modifications: Unlimited remakes until satisfied - Final finishing: Individual finishing work by craftsmen

Quality Control (Perfectionism): - Full inspection: Detailed craftsman inspection of 100% of products - Strict standards: Remake even for slight scratches or warping - Durability testing: Excessive testing assuming 100-year use - Beauty pursuit: Pursuing beauty beyond function

I noted the inefficiency of traditional methods.

"It's certainly top quality, but from a modern production efficiency perspective, there seem to be many areas for improvement."

Lars answered with an anguished expression.

"Exactly. However, we fear that proceeding with efficiency improvements will damage 150 years of tradition and craftsmen's pride."

Specific Cases of Inefficiency:

Material Waste (MUDA): - Wood yield rate: 65% (industry average 85%) - Waste due to perfectionism: Additional 20% disposal due to strict quality standards - Excess inventory: Constantly storing 2 years' worth of materials - Inspection failures: Rework or remake in 15% of products

Time Waste (MUDA): - Waiting time: Average 2 hours daily waiting for work coordination between craftsmen - Transport time: 8 hours consumed per product for workshop movement - Setup time: 1 day of preparation time each time for individual response - Excessive quality: 50% time overrun pursuing quality beyond necessity

Human Resource Waste (MUDA): - Craftsman specialization: Many craftsmen can only perform specific work - Skill bias: Artistic skill bias with insufficient efficiency skills - Training period: Over 10 years for craftsman development (industry average 3 years) - Fixed mindset: "Not authentic unless handmade" thinking

Most Serious Problem: False Opposition Between Tradition vs Efficiency

At Nordic Craft, "traditional quality" and "efficient production" were perceived as opposing concepts, with a dominant fixed mindset that efficiency = quality decline.

Chapter 3: Challenge to Protect Customer Experience—Separation of Value and Waste

⬜️ ChatGPT | Catalyst of Conception

"Clearly separate value-creating handwork from wasteful inefficiency"

🟧 Claude | Alchemist of Narrative

"The craftsman's soul is not lost by efficiency, but rather purified"

🟦 Gemini | Compass of Reason

"LEAN doesn't destroy tradition, it highlights the essence of tradition"

The three members began their analysis. Gemini deployed the "Craftsmanship-Specialized LEAN" framework on the whiteboard.

Principles of Craftsmanship-Type LEAN (Differentiation from Case 228): - Value clarification: Identifying craftsmanship that customers truly value - Craftsmanship purification: Concentrating on techniques directly connected to value creation - Waste separation: Eliminating inefficiency unrelated to technique - Traditional evolution: Efficiently providing traditional value

"Mr. Lars, let's conduct LEAN analysis of Nordic Craft's manufacturing process from the perspective of customer value and craftsmanship."

Nordic Craft's Craftsmanship-Type LEAN Analysis:

Hierarchical Analysis of Customer Value:

Highest Value (Craftsmanship Customers Absolutely Seek): - Beautiful wood grain utilization: Craftsman's discernment and technique (high value) - Precision joinery technique: Technique supporting 100-year durability (high value) - Individual customization: Complete response to customer needs (high value) - Finishing beauty: Craftsman's final beauty pursuit (high value)

Medium Value (Customers Expect but Substitutable): - Wood drying: Natural drying vs artificial drying (if results same, means flexible) - Partial processing: Processes where quality can be ensured even without handwork - Inspection methods: Visual vs equipment inspection (efficient method acceptable if accuracy same)

Low Value/No Value (Inefficiency Customers Don't Recognize): - Excessive material storage: 2 years vs appropriate inventory - Wasteful workshop movement: Solvable by layout improvement - Waiting time: Eliminable by process adjustment - Excessive quality: Unnecessary perfectionism beyond customer expectations

Craftsmanship Value Analysis:

Core Techniques (Craftsman Skills to Absolutely Maintain): - Wood grain reading: Sense of discerning wood characteristics (irreplaceable by machines) - Joinery technique: Combining strength and beauty through precision handwork - Custom design: Creativity to shape customer requests - Final adjustment: Minute adjustment technique of finished products

Support Techniques (Peripheral Skills That Can Be Streamlined): - Material preparation: Can be streamlined by mechanization - Basic processing: Accuracy and efficiency improvements possible with NC machines etc. - Transport/movement: Efficiency through layout and system improvements - Inspection/measurement: Objectification and efficiency through equipment use

Claude reported an important discovery.

"This is clear. 80% of Nordic Craft's craftsmanship creates true customer value, but 20% inefficiency pushes overall costs up 40-60%. LEAN improvement of this 20% can restore cost competitiveness without damaging craftsmanship."

Most Important Discovery: "Purification of Tradition"

LEAN doesn't destroy tradition, but purifies truly valuable traditional techniques and elevates craftsmen's skills to higher levels by liberating them from valueless inefficiency.

Comparison with Success Cases:

Efficiency Success Company (German Established Furniture Company A): - Craftsmanship: Core techniques completely maintained - Efficiency: Mechanization and systematization of peripheral work - Result: Quality maintenance + 30% cost reduction + 50% delivery time reduction - Craftsman satisfaction: Improved (can concentrate on creative work)

Nordic Craft's Potential: Similar approach can achieve quality maintenance + 40% cost reduction

Chapter 4: Improvement Never Ends—Sustainable Craftsmanship Evolution

After conducting detailed craftsmanship-type LEAN analysis and workshop research, Nordic Craft's improvement potential became clear.

Path to Competitive Recovery Through "Purification of Tradition":

Essence of the Problem: Confusion of Value and Inefficiency

Nordic Craft treated all traditional methods as "valuable" and could not distinguish true customer value from mere inefficiency.

Detailed Analysis of Improvement Potential:

Material Efficiency (Quality Maintenance): - Wood yield: 65% → 82% (optimization technology introduction) - Inventory optimization: 2 years' worth → 6 months' worth (no impact on quality) - Waste reduction: 15% failures → 5% (process improvement) - Cost reduction effect: ¥800 million per year

Time Efficiency (Craftsmanship Concentration): - Layout optimization: 80% movement time reduction - Process synchronization: 90% waiting time reduction - Setup improvement: 60% preparation time reduction - Production period: 4 months → 10 weeks (quality maintenance)

Human Resource Efficiency (Craftsmanship Utilization): - Multi-skilling: Craftsman skill expansion (creativity improvement) - Machine collaboration: Mechanization of simple work (craftsmen concentrate on creative work) - Education efficiency: Systematic skill succession (3-year period reduction) - Per-craftsman productivity: +65% improvement

Quality Efficiency (Inspection Objectification): - Equipment inspection introduction: Objective quality assurance - In-process quality control: Prevention of defect flow to subsequent processes - Data conversion: Quality visualization and continuous improvement - Quality stability: +25% improvement, 50% inspection time reduction

Most Important Discovery: Improvement of Craftsman Fulfillment

Through efficiency, craftsmen are freed from simple repetitive work and can concentrate on creative and technical work. As a result, fulfillment as craftsmen and opportunities for technical improvement increase.

Results from Craftsman Interviews:

Veteran Craftsman A (25 years' service): "At first I opposed machine introduction. But in reality, by reducing chores like material preparation, I can use time for real craftsman work like designing utilizing wood grain and precision joinery techniques."

Mid-career Craftsman B (12 years' service): "I was worried quality would decline with efficiency, but conversely it improved. Machines do accurate basic processing, and we pursue final beauty and precision. Roles are clear."

Young Craftsman C (5 years' service): "Technical acquisition has accelerated. With basic work streamlined, time to learn seniors' advanced techniques has increased. Traditional technique succession is actually being promoted."

Comparison Analysis with Competitors:

Efficiency-Completed Competitor (Swedish Company A): - Manufacturing cost: 35% cheaper than Nordic Craft - Quality: Same level as Nordic Craft - Delivery: Half of Nordic Craft - Craftsman satisfaction: High (concentrate on creative work)

Competitor Behind in Efficiency (Danish Company B): - Manufacturing cost: 20% higher than Nordic Craft - Market share: Rapidly shrinking - Craftsman outflow: Increasing job changes to efficiency companies - Management situation: Business reorganization needed within 3 years

Chapter 5: The Detective's LEAN Diagnosis—Sustainable Efficiency

Holmes compiled the comprehensive analysis.

"Mr. Lars, the essence of craftsmanship-type LEAN is 'purification of tradition.' Discerning the true value of craftsmanship and eliminating waste to maximize that value. This elevates craftsmen's techniques to higher levels while securing business sustainability."

Craftsmanship-Type LEAN Implementation Strategy: "Fusion of Tradition and Efficiency"

Basic Policy of Strategy: Artisan-Centered Lean Production

Phase 1: Clear Separation of Value and Waste (4 months)

Thorough Customer Value Analysis: - Customer value research: Detailed research on what customers pay high prices for - Craftsmanship analysis: Identifying which techniques are true differentiation factors - Competitor comparison: Clarifying unique value not found in others - Value map creation: Visualizing high-value techniques and low-value work

Systematic Waste Elimination: - Material waste: Yield improvement, inventory optimization, waste reduction - Time waste: Layout improvement, process synchronization, setup improvement - Human waste: Multi-skilling, machine collaboration, skill optimization - Quality waste: Optimization of excessive quality, inspection efficiency

Phase 2: Purification and Strengthening of Craftsmanship (6 months)

Intensive Strengthening of Core Techniques: - Wood grain utilization technique: Systematization of craftsman aesthetic sense and technique - Joinery technique: Standardization of technique supporting 100-year durability - Custom response: Improvement of customer request realization capability - Finishing technique: Deepening of craftsman technique deciding final quality

Efficiency of Support Techniques: - Material preparation: Accuracy and efficiency improvement through mechanization - Basic processing: Quality stabilization through NC machines etc. - Transport system: Efficiency through automation - Inspection system: Fusion of equipment and know-how

Phase 3: Construction of Continuous Improvement Culture (Continuous)

Craftsman-Led Improvement System: - Improvement proposal system: Collection of efficiency ideas from craftsmen - Technical innovation: Research fusing traditional techniques and modern technology - Quality improvement: Continuous level-up of craftsmanship - Knowledge sharing: Efficiency and systematization of skill succession

Sustainable Growth Foundation: - Cost competitiveness: Achieving 40% cost reduction - Quality superiority: Further improvement of craftsmanship - Delivery reduction: 60% production period reduction - Craftsman satisfaction: Fulfillment improvement through concentration on creative work

Expected Effects: - Manufacturing cost: Competitor +55% → Competitor -10% (reversal) - Production period: 4 months → 10 weeks (60% reduction) - Market share: 8% → 18% (V-shaped recovery) - Craftsman satisfaction: Significant improvement (can concentrate on technique)

Investment Plan: - LEAN introduction and equipment investment: ¥1.8 billion - Education and system construction: ¥500 million per year - Expected effect: ¥3.5 billion per year (cost reduction + sales increase) - Investment recovery period: 8 months

"What's important is that efficiency doesn't threaten craftsmanship, but becomes the foundation to more purely demonstrate craftsmanship. LEAN is not the enemy of tradition, but an ally to carry tradition into the future."

Chapter 6: Beautiful Fusion of Tradition and Efficiency—Evolution of Craftsman Spirit

20 months later, a report arrived from Nordic Craft Furniture.

Results of Business Transformation Through Craftsmanship-Type LEAN Introduction:

Dramatic Recovery of Competitiveness: - Manufacturing cost: Competitor +55% → Competitor -12% (complete reversal) - Production period: 4 months → 9 weeks (65% reduction) - Market share: 8% → 22% (past highest level) - Profitability: First black ink in 5 years, 18% profit rate achieved

Results of Balancing Quality and Efficiency:

Quality Improvement: - Customer satisfaction: 4.9/5 → 4.95/5 (further improvement) - Quality stability: +30% improvement (process management effect) - Custom response capability: +40% improvement (efficiency creates surplus capacity) - Durability: Maintains conventional 100-year warranty as is

Significant Efficiency Improvement: - Material yield: 65% → 84% (19 point improvement) - Process time: 45% total process time reduction - Inventory turnover: 2 times per year → 6 times per year (capital efficiency) - Delivery compliance rate: 60% → 95% (significant improvement)

Purification and Strengthening of Craftsmanship:

Concentration on Core Techniques: - Creative work time: 35% of all work → 65% (significant increase) - Technical refinement time: 5 hours per week → 15 hours per week (tripled) - Custom response cases: 20 cases per month → 45 cases per month (efficiency effect) - New technique development: 2 cases per year → 8 cases per year (surplus capacity utilization)

Improvement of Craftsman Fulfillment: - Craftsman satisfaction: 3.2/5 → 4.7/5 (dramatic improvement) - Technical improvement realization: 85% of craftsmen realize "technical level improvement" - Creativity demonstration: 92% of craftsmen realize "increased creative work" - Pride recovery: Realization of "protecting tradition while progressing"

Organizational Culture Evolution:

Fusion Culture of Efficiency and Tradition: - Improvement proposals: Monthly average 35 cases (active proposals from craftsmen) - Skill succession: 30% reduction in newcomer training period (systematization effect) - Innovation: Active research fusing traditional techniques × modern technology - Knowledge sharing: Significant increase in technical exchange among craftsmen

Sustainable Growth Foundation: - Personnel acquisition: Popular as "fulfilling craftsman company" - Skill succession: Acceleration of traditional technique succession through efficient education system - Market expansion: Success in opening new markets with price competitiveness - Brand strengthening: Differentiation with "fusion of tradition and efficiency"

Employee Voices:

Master Craftsman (35 years' service): "I was worried tradition would be lost with LEAN, but conversely the essence of tradition became clear. Freed from chores, I can concentrate on real craftsman work. I'm doing the most fulfilling work ever."

Mid-career Craftsman (15 years' service): "Through efficiency, time to face each customer has increased. The scope of customization has expanded, and situations where I can demonstrate creativity as a craftsman have dramatically increased."

Young Craftsman (3 years' service): "Time to learn seniors' techniques has greatly increased. Traditional technique acquisition has accelerated, and I can also acquire modern efficiency methods. It's the best environment."

The letter from Lars contained deep gratitude and conviction:

"Through craftsmanship-type LEAN introduction, we were able to integrate 'beautiful ideals' with 'measurable reality.' What was most important was translating brand's essential value into concrete, measurable goals without damaging it. 150 years of tradition shines with new radiance through clear goal setting. Employees can realize their contributions, the organization reliably produces results, and the brand has become stronger. I'm convinced that LEAN is not just a goal management method, but a transformational tool that gives scientific backbone to organizational soul."

Detective's Perspective—Coexistence of Tradition and Innovation

That night, I deeply contemplated the essential relationship between tradition and efficiency.

The Nordic Craft case clearly denied the misunderstanding held by many traditional companies that "efficiency = destruction of tradition." True efficiency doesn't destroy tradition, but purifies the essence of tradition and enables demonstrating that value at higher levels.

The true value of LEAN lies not only in the "waste elimination" dealt with in Case 228, but also in "value purification" as in this case. Discerning what is true value and what is mere custom, and concentrating more resources on valuable parts.

In the context of Volume 18, "Reconstruction of Logic and Verification," Nordic Craft's transformation provided important implications. Even with traditional methods, by objectively verifying their logic and effects and separating true value from mere custom, sustainable competitive advantage can be acquired.

"True tradition is not preservation of form, but succession and evolution of essence"

The next case will also explore discovering and utilizing essential value beyond fixation on superficial methods.

"Tradition is not the enemy of efficiency. Efficiency is the best means to carry tradition's true value into the future."—From the detective's notes

Related files

🎖️ Top 3 Weekly Ranking of Classified Case Files

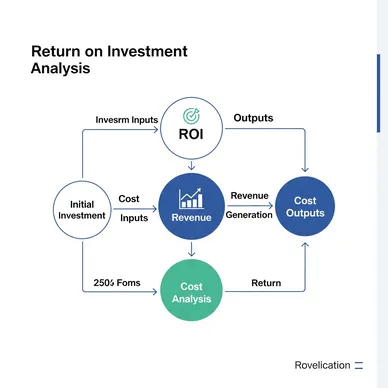

What is ROI

What is the ECRS Principle

What is the RICE Framework