ROI Case File No.267 | 'Silverline Robotics' Rapid Response Loop'

📅 2025-10-20 23:00

🕒 Reading time: 7 min

🏷️ OODA

- Chapter One: The Chain Reaction of Specification Changes - When Plans Can't Keep Up with Reality

- Chapter Two: Gathering "Only Facts" with Observe - The Purity of Observation

- Chapter Three: Drawing a Hypothesis Map with Orient - Deepening Situational Understanding

- Chapter Four: Small Iterative Decide/Act - Speed Over Perfection

- Chapter Five: The Detective's OODA Diagnosis - Responsiveness Transcends Division of Labor

- The Detective's Perspective - Speed Overwhelms Complexity

- Related files

Chapter One: The Chain Reaction of Specification Changes - When Plans Can't Keep Up with Reality

The week following the resolution of Atlas Foods' OKR case, a consultation arrived from North America regarding manufacturing responsiveness. Episode 267 of Volume 21 "Deepening Analysis" tells the story of gaining the power to judge and act instantly in unpredictable environments.

"Detective, every day at our factory is emergency response. Robots malfunction, parts don't arrive, customers demand specification changes. We make plans, but those plans have never been followed even once. The floor is exhausted."

Silverline Robotics' Production Director, Marcus Brown from Detroit, visited 221B Baker Street with an exhausted expression. In his hands were meticulous production schedules and actual records marked up in red ink showing how reality diverged.

"We manufacture industrial robots in Michigan. Our plans are perfect. But on the floor, unexpected problems occur one after another, rendering plans useless."

Silverline Robotics' Floor Chaos: - Founded: 2017 (Industrial robot manufacturing) - Monthly production: 120 units - Delivery delay rate: 45% (industry average 12%) - Emergency responses: Average 8 per day - Employee overtime: Average 65 hours/month - Customer satisfaction: 3.2/5

The numbers indicated chronic floor chaos. Marcus's expression showed deep fatigue.

"The problem is we're fixated on 'following the plan.' When gaps arise between plan and reality, we get approval, revise the plan, and execute again. That process takes time, and problems worsen further."

Pitfalls of Plan Obsession: - Monthly planning meeting: 2 days spent on detailed planning - Daily planning: Previous day plan tomorrow's work by the minute - When problems occur: Wait for supervisor approval (average 2 hours) - Specification changes: Design department re-approval needed (average 3 days) - Result: Small problems expand into major delays

"We're bound by plans and have lost the ability to make on-site decisions."

Chapter Two: Gathering "Only Facts" with Observe - The Purity of Observation

"Mr. Brown, when problems occur on the floor, what kind of information gathering happens?"

To my question, Marcus answered bitterly.

"Basically we compile 'what happened' into reports. But those reports mix the person's interpretation and speculation, often making facts unclear."

Current Information Gathering (Mixed Interpretation):

Case: Robot Arm Malfunction - Report: "Arm not moving properly. Probably motor failure" - Problem: "Probably" speculation mixed with fact - Response: Applied for motor replacement approval - Result: Actually sensor misconfiguration, 3 days wasted

I explained the importance of separating facts from interpretation.

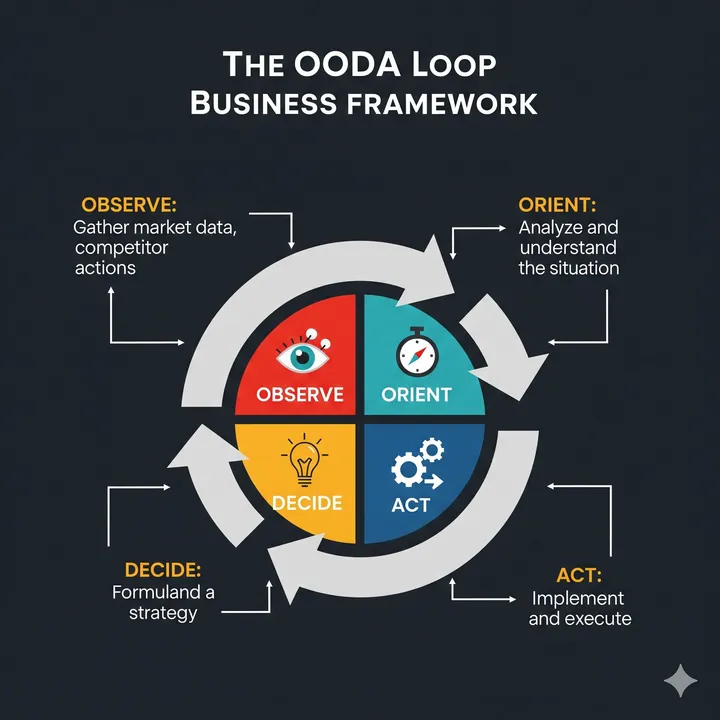

"Observe - observation. This is the first stage of the OODA Loop. What matters here is strictly separating fact from interpretation. Record only 'what was seen,' and think about 'why it happened' at the next stage."

⬜️ ChatGPT | Catalyst of Concepts

"Observe, Orient, Decide, Act. Spin these four fastest."

🟧 Claude | Alchemist of Narratives

"The floor is alive. Plans are merely maps. Trust the scenery you see now over maps."

🟦 Gemini | Compass of Reason

"OODA is the art of rapid response. Observation over planning, action over approval."

The three members began their analysis. Gemini deployed the "Manufacturing Floor-Specific OODA" framework on the whiteboard.

OODA Loop's 4 Stages: - Observe - Gather facts - Orient - Read meaning from facts - Decide - Determine course of action - Act - Execute immediately

"Mr. Brown, let's accelerate Silverline's floor with the OODA Loop."

Chapter Three: Drawing a Hypothesis Map with Orient - Deepening Situational Understanding

Phase 1: Observe Training (2 weeks)

First, we trained all floor staff to "report only facts."

Observe Training Example:

Bad Report (Mixed Interpretation): "Robot arm malfunctioned. I think the motor is bad."

Good Report (Facts Only): - Arm shifted 3cm left from set position - Error code "E-247" displayed - Motor temperature normal range (45°C) - No abnormal noise - Yesterday's operation was normal

Phase 2: Structuring Orient (1 month)

Next, we standardized how to judge situations from observed facts.

Orient (Situation Judgment) 3 Steps:

Step 1: Pattern Recognition - Search past similar cases - Error code "E-247" → 85% sensor system trouble

Step 2: Hypothesis Construction - Hypothesis A: Position sensor misconfiguration (60% probability) - Hypothesis B: Control software bug (30% probability) - Hypothesis C: Mechanical failure (10% probability)

Step 3: Impact Assessment - If Hypothesis A: 15-minute recovery possible - If Hypothesis B: 2-hour investigation needed - If Hypothesis C: 1-day parts replacement

Phase 3: Delegating On-Site Decision Authority

The most important transformation was delegating authority to the floor.

New Rules: - Impact within 1 hour: On-site decision, immediate response - Impact within 1 day: Team leader decision - Impact exceeding 1 day: Report to management

Case: Robot Arm Malfunction Response

Observe: - Confirmed 3cm arm shift, error E-247 - Report time: 10:15

Orient: - Pattern: E-247 high probability sensor misconfiguration - Hypothesis: Resolved by position sensor recalibration (60% probability) - Impact: 15-minute trial, if fail 30 minutes for alternative response

Decide: - On-site engineer decision: Execute sensor recalibration

Act: - 10:20 Start calibration - 10:32 Recovery complete - 10:35 Resume production

Conventional Response: - 10:15 Problem discovered - 10:30 Submit report to supervisor - 12:00 Supervisor approval - 14:00 Inquiry to design department - Next day 10:00 Start response - Total: 24-hour delay

OODA Response: - 10:15 Problem discovered - 10:35 Recovery complete - Total: 20 minutes

Chapter Four: Small Iterative Decide/Act - Speed Over Perfection

Phase 4: Shift from High-Speed PDCA to OODA (3 months)

The entire organization's decision-making culture began changing.

Manufacturing Floor Changes:

Conventional (PDCA Focus): - Plan: Detailed planning upfront - Do: Execute according to plan - Check: Verify results - Act: Reflect in next plan

Problem: Planning takes time, flexible response during execution impossible

Current (OODA Focus): - Observe: Continuously observe floor conditions - Orient: Judge situation instantly - Decide: Immediate policy decision - Act: Try small, return to observation

Effect: Immediate response to floor changes, early problem resolution possible

Ripple to Design Department:

Specification Change Response Changes

Conventional: - Customer specification change request - Design department 3-day detailed review - Approval meeting 2 days - Instructions to manufacturing - Total: 5-7 days

Post-OODA Introduction: - Customer specification change request - Observe: Immediately grasp change content and impact scope - Orient: Judge response pattern from past similar changes - Decide: Immediate decision if standard change, partial prototyping if special - Act: Start response same day - Total: Few hours to 1 day

Results After 6 Months:

Dramatic Production Metrics Improvement: - Delivery compliance rate: 55% → 92% - Emergency response count: 8/day → 1.5/day - Average overtime hours: 65 hours/month → 18 hours/month - Customer satisfaction: 3.2 → 4.6

Organizational Culture Changes: - Floor autonomy: Wait for instructions → Autonomous judgment - Decision-making speed: Average 2 hours → Average 15 minutes - Inter-department coordination: Vertical silos → Horizontal collaboration

Employee Voices:

Floor Engineer (34 years old): "Before, waiting for supervisor approval was painful. Now I can judge and act myself. Responsibility is heavy but rewarding."

Design Staff (29 years old): "OODA united floor and design. We share information real-time and can decide solutions on the spot."

Chapter Five: The Detective's OODA Diagnosis - Responsiveness Transcends Division of Labor

Holmes compiled the comprehensive analysis.

"Mr. Brown, the essence of OODA is 'responsiveness.' Quick observation and judgment over perfect plans. Autonomous on-site action over approval. In unpredictable environments, plans are merely maps. The courage to trust the scenery you see and proceed - that strengthens organizations."

Final Report After 12 Months:

Silverline Robotics transformed into a company boasting industry-leading delivery reliability.

Final Results: - Delivery compliance rate: 55% → 96% (industry top) - Monthly production: 120 → 180 units (50% increase) - Customer satisfaction: 3.2 → 4.8 - Employee satisfaction: 3.5 → 4.7 (increased autonomy)

Marcus's letter contained profound learning:

"Through OODA, we transformed from 'an organization bound by plans' to 'an organization where the floor lives.' What mattered most was the cultural shift valuing quick action over perfect plans. Now design, production, and maintenance unite and respond immediately to the reality before us. Plans are important, but the floor is more important - we've learned that."

The Detective's Perspective - Speed Overwhelms Complexity

That evening, I contemplated the essence of responsiveness.

The true value of the OODA Loop lies in how it confronts uncertainty. Plans seek certainty. But floors are always unpredictable. Then rather than improving plan accuracy, improve observation and judgment speed.

When speed increases, even if you fail, you can correct quickly. That accumulation produces results exceeding plans.

"There are no perfect plans on the battlefield. Only the victory of those who observe quickly, judge, and move."

The next case will also depict the moment when responsiveness opens an organization's future.

"Plans are beautiful. But reality is ugly. Only those who can respond to ugly reality obtain beautiful results." - From the Detective's Notes

Related files

🎖️ Top 3 Weekly Ranking of Classified Case Files

What is MVP

What is Agile Development

What is STP Analysis