ROI Case File No.308 | 'AutoForge's Invisible Defects'

📅 2025-11-10 11:00

🕒 Reading time: 8 min

🏷️ DOUBLE_DIAMOND

- Chapter 1: The Invisible Enemy—0.3% Defects Shake Company

- Chapter 2: The Surface Trap—Danger of Jumping to Solutions

- Chapter 3: 1st Diamond—Unearthing Problem Essence

- Chapter 4: 2nd Diamond—Creating Solutions

- Chapter 5: Zero as Proof—Results After 12 Months

- Chapter 5: Detective's Diagnosis—Two Diamonds Illuminate Truth

- Related Files

Chapter 1: The Invisible Enemy—0.3% Defects Shake Company

The week after resolving TransLog's LEAN incident, a consultation arrived from Tochigi regarding an auto parts manufacturer's quality control. Episode 308 of Volume 25 "The Pursuit of Certainty" tells the story of not mistaking problem essence, repeatedly diverging and converging to reach true solutions.

"Detective, our inspection process has serious problems. Of manufactured parts, 0.3% reach customers as defects. Auto manufacturer complained. 'If defects continue, we'll review the transaction.' But we don't know what or how to improve."

Seiichi Takahashi, quality control manager at AutoForge Inc., originally from Utsunomiya, visited 221B Baker Street with a grave expression. In his hands were customer complaint records and, in stark contrast, quality meeting minutes stamped "Cause Unknown."

"We manufacture auto parts in Tochigi. Precision parts around engines, brake parts. Annual production 1.2 million units. Of which, 0.3%—3,600 units—discovered as defects at customer sites."

AutoForge's Quality Crisis: - Establishment: 1985 (Auto parts manufacturing) - Annual Revenue: ¥4.2 billion - Employees: 180 - Annual Production: 1.2 million units - Defect Outflow Rate: 0.3% (3,600 units/year) - Customers: 3 major auto manufacturers - Inspection System: Visual inspection (24 inspectors) - Problem: Defects discovered at customer sites (slipping through inspection)

Deep anxiety filled Takahashi's voice.

"The problem is that parts we judged 'pass' in our inspection are judged 'defect' at customer sites. So our inspection isn't functioning. But inspectors inspect seriously. Why miss defects...?"

Recent Major Complaint (1 month ago):

Customer: Auto Manufacturer A "Internal cracks discovered in brake parts delivered from your company. This caused assembly line stoppage for 2 hours. Damage about ¥8M. If similar defects occur 3 more times, we'll review the transaction"

AutoForge's Response: - Recalled applicable lot (1,000 units) - Re-inspection: 952 passed, 48 defects (4.8% defect rate) - Discovery: Internal cracks invisible to visual inspection

Problem Essence: "Our inspection only looks at surface. Missing internal defects"

"Received final warning from Company A. 'Improve inspection system within 3 months or we'll reduce transactions.' Annual ¥1.8B transaction. Can't afford to lose it."

Chapter 2: The Surface Trap—Danger of Jumping to Solutions

"Mr. Takahashi, what improvement measures are you currently considering?"

To my question, Takahashi answered.

"Thinking about increasing inspectors. From 24 to 30. And extending inspection time from 2 minutes to 3 minutes per unit. If we inspect more carefully, shouldn't miss defects..."

Current Improvement Plan (Superficial): - Measure: Increase inspectors, extend inspection time - Premise: "If humans look, they'll find defects" - Problem: Internal cracks invisible to visual inspection

I explained the importance of identifying problem essence.

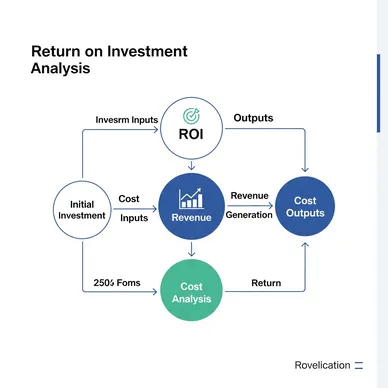

"Before jumping to solutions, need to identify problem essence. Double Diamond—diverge and converge twice. Explore essence in problem space, find optimal solution in solution space. These 2 stages lead to true resolution."

⬜️ ChatGPT | Catalyst of Vision

"Don't give answers immediately. With Double Diamond, first expand problem, narrow, then expand solutions, narrow"

🟧 Claude | Alchemist of Stories

"Those who think solutions at problem surface miss the root. Two diamonds illuminate truth"

🟦 Gemini | Compass of Reason

"Double Diamond is thinking technique. Expand possibilities by diverging, narrow essence by converging. Repeat twice"

The three members began analysis. Gemini developed the "Double Diamond Framework" on the whiteboard.

Double Diamond's 4 Stages:

【1st Diamond: Problem Space】

1. Discover: Broadly explore problems

2. Define: Narrow to essential problem

【2nd Diamond: Solution Space】

3. Develop: Broadly ideate solutions

4. Deliver: Narrow to optimal solution

"Mr. Takahashi, let's solve AutoForge's inspection problem with Double Diamond."

Chapter 3: 1st Diamond—Unearthing Problem Essence

Phase 1: Discover - Diverge (4 weeks)

First, broadly explored problems. Not just the surface "defects flow out," but examined problems from all angles.

Investigation 1: Defect Analysis (2 weeks)

Analyzed 3,600 defective units discovered at customer sites over past year.

Defect Types: - Internal cracks: 1,800 units (50%) - Surface scratches: 720 units (20%) - Dimensional defects: 540 units (15%) - Foreign material contamination: 360 units (10%) - Other: 180 units (5%)

Discovery: 50% of defects are "internal cracks"—invisible to visual inspection

Investigation 2: Inspection Process Observation (1 week)

Stuck to inspection site, observed inspector work.

Inspector Work (2 min per unit): 1. Pick up part (5 sec) 2. Visually check surface (60 sec) 3. Measure dimensions with calipers (40 sec) 4. Judge pass/fail (5 sec) 5. Move to next part (10 sec)

Discovery: - Inspection only "surface" and "dimensions" - Internal completely unexamined - Inspectors recognize "can't find internal cracks"

Inspector A's Testimony: "Internal cracks aren't visible to eyes. But can't X-ray inspect all units. Costs too much. So only inspect surface"

Investigation 3: Manufacturing Process Observation (1 week)

Investigated which process generates internal cracks.

Manufacturing Process: 1. Material input 2. Casting (melt metal, pour into mold) 3. Cooling 4. Cutting 5. Heat treatment 6. Inspection 7. Shipping

Investigation Results: - Internal crack cause: Uneven cooling during casting - Occurrence frequency: About 0.5% (internal cracks in 0.5% of total) - Capture rate in inspection: 40% (remaining 60% flow out)

Discovery: Internal cracks already exist at manufacturing stage. Inspection misses 60%.

Investigation 4: Customer Quality Standards (1 week)

Investigated what customers judge as "defects."

Auto Manufacturer A's Quality Standards: "Internal cracks 0.1mm+ are defects. Even if not appearing on surface"

AutoForge's Inspection Standards: "Pass if no surface scratches"

Discovery: Customer standards "include internal," AutoForge standards "surface only"—misaligned standards

Phase 2: Define - Converge (1 week)

Organized information from 4-week discovery phase, defined essential problem.

Problem Essence:

"AutoForge's inspection is limited to 'surface inspection.' However, 50% of defects are 'internal cracks,' undiscoverable by visual inspection. Customer quality standards require 'complete inspection including internal,' but AutoForge can't respond. As a result, 0.3% defects discovered at customer sites, facing transaction reduction risk."

True Challenge: "Building inspection system capable of detecting internal cracks"

Takahashi nodded deeply.

"The measure 'increase inspectors' was surface treatment. The essence was 'lacking technology to see internal.'"

Chapter 4: 2nd Diamond—Creating Solutions

Phase 3: Develop - Diverge (3 weeks)

With clear problem essence, broadly ideated solutions.

Brainstorming (30 participants): - Quality Control: 10 - Manufacturing: 10 - Technology Development: 10

Rules: - No criticism, emphasize quantity, free and unrestrained

Ideas (partial, 68 total):

Category 1: Inspection Technology Introduction 1. Introduce X-ray inspection equipment 2. Introduce ultrasonic inspection equipment 3. Introduce CT (computed tomography) 4. Introduce electromagnetic inspection 5. Detect fine surface changes with AI camera

Category 2: Manufacturing Process Improvement 6. Standardize casting cooling speed 7. Improve material quality 8. Optimize heat treatment conditions

Category 3: Sampling Inspection 9. Not full inspection but sampling 10. Manage defect rate with statistical methods

Category 4: Hybrid Inspection 11. Combine visual + X-ray inspection 12. Collaborative AI and human inspection

... (56 more)

Phase 4: Deliver - Converge (2 weeks)

Evaluated 68 ideas, narrowed to optimal solution.

Evaluation Axes: 1. Technical feasibility 2. Cost 3. Inspection accuracy 4. Inspection time

Evaluation Results:

Plan 1: X-ray Inspection Equipment (Full Inspection) - Accuracy: ◎ (100% internal crack detection) - Cost: × (¥100M equipment, full inspection time-consuming) - Inspection Time: × (5 min/unit, 6M min annually = unrealistic)

Plan 2: Ultrasonic Inspection Equipment (Full Inspection) - Accuracy: ◎ (95% internal crack detection) - Cost: ○ (¥35M equipment) - Inspection Time: △ (1 min/unit, 1.2M min annually = barely possible)

Plan 3: AI Camera + Ultrasonic Hybrid Inspection - Accuracy: ◎ (Surface 95%, Internal 95%) - Cost: ○ (AI camera ¥12M + ultrasonic ¥35M = ¥47M) - Inspection Time: ○ (45 sec/unit, 900K min annually = realistic) - Hybrid Effect: AI instantly judges surface, ultrasonic only inspects suspicious ones

Final Decision: Plan 3 (AI Camera + Ultrasonic Hybrid Inspection)

Implementation Plan: 1. AI camera for surface inspection (20 sec/unit) 2. Only items AI judges "suspected internal crack," ultrasonic inspection (25 sec/unit) 3. Ultrasonic inspection target: About 10% of total (0.5% internal crack occurrence + safety margin) 4. Total inspection time: Average 45 sec/unit

Phase 5: System Introduction (6 months)

Investment: - AI camera system: ¥12M - Ultrasonic inspection equipment: ¥35M - System integration: ¥8M - Inspector training: ¥2M - Total: ¥57M

Operation After 6 Months: - Inspection line: Automation + human monitoring - Inspectors: 24 → 8 (AI main, humans assist) - Inspection time: 2 min/unit → 45 sec (62% reduction)

Chapter 5: Zero as Proof—Results After 12 Months

Quality Results After 12 Months:

Defect Outflow Rate: - Before: 0.3% (3,600 units/year) - After: 0.02% (240 units/year, 93% reduction)

Internal Crack Detection Rate: - Before: 40% - After: 98%

Customer Complaints: - Before: Monthly average 12 - After: Monthly average 0.8 (93% reduction)

Evaluation from Auto Manufacturer A: "AutoForge's quality dramatically improved. Internal crack defects nearly zero. Considering expanding transactions"

Transaction Expansion: - Orders from Company A: Annual ¥1.8B → ¥2.4B (+33%) - New Customer Acquisition: 2 companies ("high quality" appreciated)

Financial Results:

Investment Recovery: - Investment: ¥57M - Complaint response cost reduction: ¥24M annually - Inspector labor cost reduction: ¥16M annually - Revenue increase: ¥600M annually - Investment Recovery Period: 1.4 years

Organizational Change:

Quality Control: "Recognized visual inspection limits. Technology supplementation enables inspection beyond human capability"

Manufacturing: "Improved not just inspection but manufacturing process. Standardizing casting cooling reduced internal crack occurrence 0.5% → 0.2%"

Management: "Double Diamond identified problem essence. Not symptomatic treatment 'increase inspectors' but root treatment 'technology to see internal'"

Chapter 5: Detective's Diagnosis—Two Diamonds Illuminate Truth

That night, I contemplated Double Diamond essence.

Initially AutoForge tried jumping to measure "increase inspectors." But that was only surface treatment.

In 1st Diamond (problem space), broadly explored problems, discovered essence "internal cracks invisible." Then defined problem as "lacking technology to see internal."

In 2nd Diamond (solution space), broadly ideated solutions, narrowed to optimal solution "AI camera + ultrasonic hybrid inspection."

"Don't think solutions at problem surface. Diverge and converge with two diamonds. True resolution lies beyond."

The next case will also depict the moment Double Diamond illuminates essence.

"Don't give answers immediately. Expand by diverging, narrow by converging. Repeat twice. Double Diamond leads to true resolution"—From the Detective's Notes

Related Files

🎖️ Top 3 Weekly Ranking of Classified Case Files

What is STP Analysis

What is ROI

What is the RICE Framework