ROI Case File No.333 | 'The 14-Digit Code of SkyNet Solutions'

📅 2025-11-24 23:00

🕒 Reading time: 9 min

🏷️ PDCA

- Chapter 1: The Anachronism of FAX — 90% of Orders Arrive Analog

- Chapter 2: The Expectation of AI-OCR — Reading Alone Doesn't Solve It

- Chapter 3: The Challenge of Learning — Training with 1,000 Data Points

- Chapter 4: Liberation Through Automation — Changes After 6 Months

- Chapter 5: Detective's Diagnosis — AI Evolves Through Repeated Improvement

- Related Files

Chapter 1: The Anachronism of FAX — 90% of Orders Arrive Analog

The week after the Arcturus Corp sales optimization case was solved, a consultation about order processing automation arrived. Volume 27, "The Pursuit of Reproducibility," Episode 333 tells the story of battling between analog and digital.

"Detective, 90% of our orders come by FAX. In 2025, can you believe it? And 20 order processing staff struggle with FAX daily."

Yuichi Tanaka, Business Improvement Director of SkyNet Solutions, originally from Osaka, visited 221B Baker Street with a wry smile. In his hands, he held copies of handwritten order forms alongside contrasting business flow diagrams marked "Product Code Identification: Manual."

"We're in the wholesale business for industrial parts. We have approximately 1,200 client companies. Most are small and medium-sized town factories. They send order forms by FAX. Not email or EDI. FAX."

SkyNet Solutions' Order Processing Structure: - Established: 1987 (industrial parts wholesale) - Annual revenue: 5.8 billion yen - Client companies: 1,200 - Monthly order volume: Approximately 4,500 - FAX order rate: 90% (4,050) - Order processing staff: 20 members - Problem: FAX order forms don't include core system product codes, requiring manual identification

Tanaka's voice carried deep fatigue.

"The problem is that order forms sent by FAX don't include our core system product codes. 14 to 15-digit alphanumeric product codes — like 'AB1234-CD5678-EF90' — these don't exist. Instead, only information like 'Product name: Stainless steel bolt, Color: Silver, Size: M8×50mm, Carton: 10-piece pack' is written."

Typical Order Form Examples:

Order Form A (Town Factory X):

Item: Stainless steel bolt

Color: Silver

Size: M8×50mm

Carton: 10-piece pack

Quantity: 5 cartons

Core System Product Code:

AB1234-ST0850-CT10

Order Form B (Town Factory Y):

Item: Hex nut

Material: Iron

Size: M10

Loose: 1-piece unit

Quantity: 200 pieces

Core System Product Code:

HN5678-IR1000-BR01

Tanaka sighed deeply.

"Order processing staff search the core system for applicable product codes based on order form information. This takes an average of 3 minutes per order. At 4,500 monthly, that's 13,500 minutes total. 225 hours. Twenty staff members are consumed by this task every month."

Chapter 2: The Expectation of AI-OCR — Reading Alone Doesn't Solve It

"Tanaka-san, have you considered implementing AI-OCR?"

To my question, Tanaka nodded.

"Yes, we actually tried three AI-OCR services. But none solved it. AI-OCR can read FAX characters. 'Stainless steel bolt,' 'M8×50mm,' '10-piece pack.' It can convert these to digital data. However, it cannot convert that to our core system's 14-digit product codes."

Current Understanding (AI-OCR Standalone Model): - Strategy: Character reading with AI-OCR - Problem: Cannot link read data to product codes

I explained the importance of automation combining AI-OCR with machine learning.

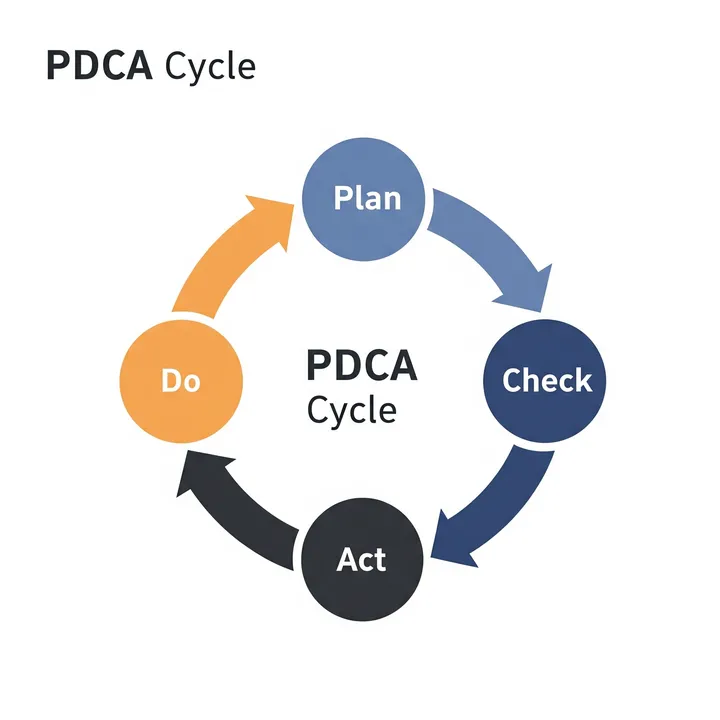

"The problem isn't 'reading' but 'identification.' Identifying applicable product codes from multiple pieces of information like product name, color, size, carton/loose. This is a pattern recognition and learning problem. PDCA — Plan, Do, Check, Act. By repeating planning, execution, evaluation, and improvement, AI increases product code identification accuracy."

⬜️ ChatGPT | Catalyst of Concepts

"Reading alone is insufficient. Identify. Run PDCA with AI-OCR + machine learning."

🟧 Claude | Story Alchemist

"14-digit product codes always exist in 'patterns.' Make it learn those patterns."

🟦 Gemini | Compass of Reason

"PDCA is improvement technology. Repeat plan, execute, evaluate, improve to approach 100% accuracy."

The three members began analysis. Gemini displayed the "PDCA Framework" on the whiteboard.

PDCA's 4 Elements: 1. Plan: Set goals and methods 2. Do: Execute the plan 3. Check: Evaluate results 4. Act: Improve based on evaluation

"Tanaka-san, let's develop an AI order agent. And increase accuracy with PDCA."

Chapter 3: The Challenge of Learning — Training with 1,000 Data Points

Phase 1: Plan — 3 weeks

First, established the AI order agent development plan.

Goals: - Automatically identify core system product codes from FAX order forms - Accuracy: 95%+ - Processing time: Within 10 seconds per order

Development Requirements: - AI-OCR: Digitize FAX characters - Machine learning model: Identify product codes from product name, color, size, carton/loose - Core system integration: Automatically input identified product codes

Training Data: - Past year's order forms: 4,500 × 12 months = 54,000 - Use 1,000 as training data - Link correct product codes to each order form

Phase 2: Do (Execution) — 6 weeks

Step 1: AI-OCR Implementation (2 weeks) - Tool: A certain AI-OCR service (97% recognition accuracy) - Extract text data from FAX images - Output: Product name, color, size, carton/loose, quantity

Step 2: Machine Learning Model Construction (3 weeks) - Algorithm: Random Forest (decision tree-based classification model) - Training data: 1,000 order forms and correct product codes - Features: - Product name (categorical variable: bolt, nut, washer, etc.) - Material (categorical variable: stainless steel, iron, brass, etc.) - Size (numerical variable: M8, M10, M12, etc.) - Color (categorical variable: silver, black, gold, etc.) - Carton/loose (categorical variable: 10-piece pack, 50-piece pack, loose, etc.)

Step 3: Core System Integration (1 week) - Built API to automatically input identified product codes to core system - Order processing staff confirms, then presses confirm button

Phase 3: Check (Evaluation) — 4 weeks

First Test (200 items outside training data): - Accuracy: 78% - Breakdown of errors: - Carton/loose judgment errors: 12% (24 items) - Size judgment errors: 7% (14 items) - Product name judgment errors: 3% (6 items)

Problem Analysis:

Case 1: Carton/Loose Judgment Error - Order form notation: "10 pieces" - AI judgment: "Loose 10 pieces" (product code: ~BR10) - Correct answer: "Carton 10-piece pack" (product code: ~CT10) - Cause: "10 pieces" notation is ambiguous, can't determine carton or loose

Case 2: Size Judgment Error - Order form notation: "M8" - AI judgment: "M8×40mm" (product code: ~0840) - Correct answer: "M8×50mm" (product code: ~0850) - Cause: When length notation absent, set wrong default value

Phase 4: Act (Improvement) — 3 weeks

Improvement 1: Strengthen Carton/Loose Judgment Logic - Additional rule: When "10 pieces" notation exists, check past order history - If same client frequently ordered "Carton 10-piece pack" in past, judge as carton - If no past history, prompt order processing staff for confirmation

Improvement 2: Revise Size Default Values - When length notation absent, reference "most frequent size" by product category - Example: For stainless steel bolt M8, 78% of past data is "50mm" → Set default to 50mm

Improvement 3: Add Training Data - Increase from 1,000 to 2,000 - Focus on adding data for categories with many misjudgments

Second Test (200 items): - Accuracy: 91% - Breakdown of errors: - Carton/loose judgment errors: 5% (10 items) - Size judgment errors: 3% (6 items) - Product name judgment errors: 1% (2 items)

Third Test (500 items): - Accuracy: 96% - Breakdown of errors: - Carton/loose judgment errors: 2% (10 items) - Size judgment errors: 1% (5 items) - Product name judgment errors: 1% (5 items)

Goal Achieved: 95%+ accuracy

Chapter 4: Liberation Through Automation — Changes After 6 Months

Phase 5: Production Operation (6 months)

Operation Flow:

Step 1: FAX Reception - Order forms arrive by FAX (4,050 monthly)

Step 2: AI Order Agent Automatic Processing - AI-OCR character reading (10 seconds) - Machine learning model product code identification (5 seconds) - Input to core system (5 seconds) - Total: 20 seconds/order

Step 3: Order Processing Staff Confirmation - Confirm product code identified by AI - With 96% accuracy, mostly confirm as-is - Only 4% errors (162 items) manually corrected - Confirmation time: 30 seconds/order

Step 4: Finalization - Press confirm button to complete order

Results After 6 Months:

Work Time Reduction: - Before: 3 minutes per order × 4,050 orders = 12,150 minutes (202.5 hours/month) - After: 30 seconds per order × 4,050 orders = 2,025 minutes (33.75 hours/month) - Reduction: 168.75 hours/month (83% reduction)

Labor Cost Reduction: - Before: 20 order processing staff, 202.5 monthly hours for FAX processing - After: 20 order processing staff, reduced to 33.75 hours - 168.75 reduced hours allocated to other work (customer support, inventory management, etc.)

Annual Cost Reduction: - Hourly rate: 2,500 yen (order processing staff average) - Reduced hours: 168.75 hours/month × 12 months = 2,025 hours/year - Reduced cost: 2,025 hours × 2,500 yen = 5.06 million yen/year

Continuous Accuracy Improvement:

Accuracy After 6 Months: - Accuracy: 98% - Reason: Added incorrect data to training data during operation, retrained model

Annual Order Volume: - 48,600 orders (4,050 × 12 months) - Correct: 47,628 orders (98%) - Incorrect: 972 orders (2%)

The 972 incorrect orders can be manually corrected in 30 seconds, no problem

Organizational Changes:

Order Processing Staff Voices:

Staff Member A: "Previously, I battled mountains of FAX daily. Taking 3 minutes per order, processing 40 daily was the limit. But after AI introduction, my job became just 'confirmation.' Look at the product code AI identified, think 'that's correct,' press confirm button. I can now process 100+ daily."

Staff Member B: "Initially, I worried 'will AI take my job?' But actually, it was different. AI just does simple tasks for us. We can now spend that time on higher-value work like customer phone support and inventory optimization."

Tanaka's Feedback:

"Until running PDCA, we thought 'implementing AI-OCR will solve it.' But that was wrong. Reading alone was insufficient; we needed to identify product codes.

Plan: Prepared 1,000 training data points. Do: Constructed machine learning model. Check: Started at 78% accuracy, analyzed problems. Act: Strengthened logic, added training data. And achieved 96% accuracy.

Six months after operation start, accuracy improved to 98%. By continuously running PDCA, AI continues to grow. We achieved 5.06 million yen annual cost reduction and order processing staff burden relief."

Chapter 5: Detective's Diagnosis — AI Evolves Through Repeated Improvement

That evening, I contemplated the essence of AI implementation.

SkyNet Solutions was trapped in the illusion that "implementing AI-OCR will solve it." However, the problem wasn't reading but product code identification.

By repeating plan, execution, evaluation, and improvement with PDCA, AI evolved from 78% to 98%. And achieved 5.06 million yen annual cost reduction and order processing staff liberation.

"AI isn't magic. It evolves through repeated improvement. Run PDCA, increase accuracy, automate operations. 14-digit codes are no longer codes."

The next case will also depict the moment of repeating improvement with PDCA.

"Reading alone is insufficient. Identify. Run PDCA with AI-OCR + machine learning to approach 100% accuracy. 14-digit product codes exist within patterns." — From the Detective's Notes

Related Files

🎖️ Top 3 Weekly Ranking of Classified Case Files

What is MVP

What is Agile Development

What is STP Analysis