ROI Case File No.287 | 'BuildMach's AI Construction Equipment Challenge'

📅 2025-10-30 23:00

🕒 Reading time: 9 min

🏷️ OODA

- Chapter 1: The AI Implementation Labyrinth — Challenge to an Unplannable Future

- Chapter 2: Loops of Observation and Judgment — Adaptation, Not Planning

- Chapter 3: First Loop — Starting from Small Observations

- Chapter 4: Loops 2-4 — Accelerating Observe-Orient-Decide-Act

- Chapter 5: The Detective's OODA Diagnosis — Technology for Making Uncertainty an Ally

- The Detective's Perspective — Plans Are Comfort, Adaptation Is Growth

- Related files

Chapter 1: The AI Implementation Labyrinth — Challenge to an Unplannable Future

The week following the resolution of Foodlink's Jobs Theory case, a consultation arrived from central Japan regarding a construction machinery manufacturer's AI strategy. Episode 287 of Volume 23 "The Pursuit of Reproducibility - Sequel" tells the story of realizing technological innovation with high uncertainty through flexible decision-making loops.

"Detective, management ordered 'utilize AI.' But no one knows where to begin. We try to define requirements, but what AI can do remains unclear. We try to create plans, but technology evolves too fast for plans to keep up."

BuildMach's technical planning manager, Daisuke Yamada from Nagoya, visited 221B Baker Street unable to hide his confusion. In his hands were a planning document titled "AI Utilization Promotion Plan" that remained blank, and in stark contrast, mountains of AI-related materials.

"We manufacture construction machinery like excavators and bulldozers in Aichi Prefecture. To avoid falling behind the digitalization wave, management made 'AI utilization' company policy. But the field is in chaos."

BuildMach's AI Confusion: - Founded: 1978 (construction machinery manufacturer) - Annual revenue: $317 million - Employees: 1,200 - AI promotion project start: 1 year ago - Time invested: Cumulative 3,600 hours (meetings and research) - AI implementation results: 0 - Projects under consideration: 12 (all undecided) - Field voices: "Don't understand concretely what to do"

Deep anxiety showed on Yamada's face.

"The problem is we're trying to 'create a perfect plan.' Research what AI can do, define requirements, create development plans, secure budgets, then start. This conventional approach doesn't work for AI implementation."

Failed Plan-Based Approach:

Consideration Project A: Excavator Automatic Excavation - Phase 1: Market research (3 months) → "Potential exists" - Phase 2: Technical research (4 months) → "Many challenges for realization" - Phase 3: Requirements definition (6 months) → "Requirements won't solidify" - Result: 13 months elapsed, cannot start

Consideration Project B: AI Analysis of Operation Data - Phase 1: Use case consideration (2 months) → "Various possibilities" - Phase 2: Data collection method consideration (3 months) → "Existing equipment insufficient" - Phase 3: ROI calculation (5 months) → "High uncertainty, calculation impossible" - Result: 10 months elapsed, cannot start

Management Frustration: "A year has passed and nothing has taken shape. Just creating plans without execution?"

Field's Position: "If we start without plans and fail, who takes responsibility? AI has too much uncertainty to plan."

"We have a 'plan before execution' culture. But in uncertain domains like AI, that culture becomes a shackle."

Chapter 2: Loops of Observation and Judgment — Adaptation, Not Planning

"Mr. Yamada, what process guides your current AI promotion?"

To my question, Yamada answered.

"Basically PDCA. Create a perfect Plan before moving to Do. But with AI, perfect plans can't be created. Technology evolves daily, capabilities change. While creating plans, situations change."

Current Approach (Plan-Focused): - Premise: "Success if plan is perfect" - Process: Plan (long-term) → Do (short-term) - Problem: Can't plan in high uncertainty domains - Result: Never reaches execution

I explained the importance of flexible decision-making responsive to situations.

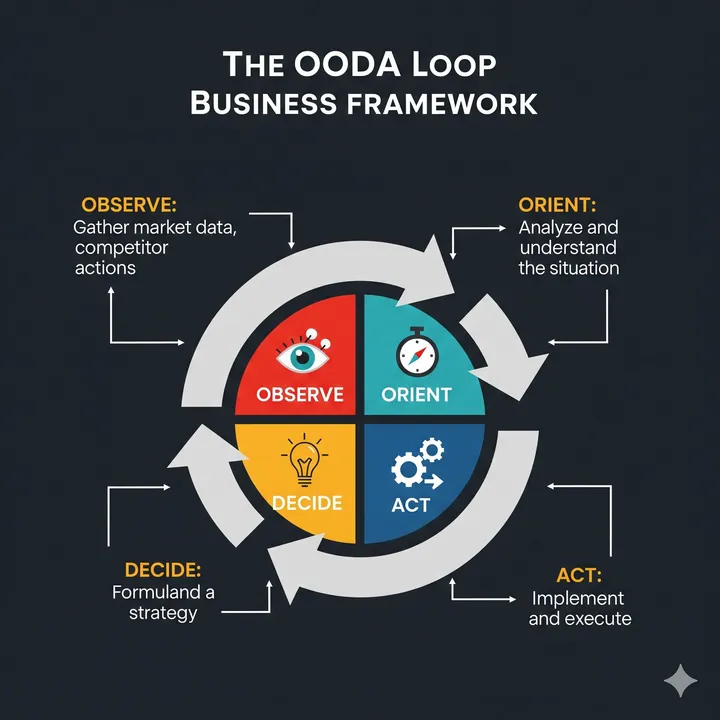

"In uncertain domains, plans are useless. OODA—Observe, Orient, Decide, Act. By spinning this high-speed loop, we adapt to changes while advancing."

⬜️ ChatGPT | Catalyst of Concepts

"In an uncertain world, plans are illusions. Observe, orient, decide, act. Then repeat."

🟧 Claude | Alchemist of Narratives

"Those waiting for perfect maps never depart. Only those who walk with imperfect compasses reach destinations."

🟦 Gemini | Compass of Reason

"OODA is adaptation technology. Read environment, judge, act. Spin it fast."

The three members began analysis. Gemini deployed an "AI Implementation-Specific OODA Analysis" framework on the whiteboard.

OODA Loop Four Stages: 1. Observe - Observe current state and environment 2. Orient - Judge situation from observed information 3. Decide - Decide what to do next 4. Act - Execute decisions

Differences from PDCA: - PDCA: Emphasizes planning, long cycles - OODA: Emphasizes observation, fast cycles

"Mr. Yamada, let's advance BuildMach's AI implementation with OODA loops."

Chapter 3: First Loop — Starting from Small Observations

Phase 1: Observe (1 week)

First, we abandoned creating perfect plans and started with field "observation."

Observation Target: Own construction sites (3 locations)

Observation Items: - Excavator operation status - Operator work patterns - Equipment stop and standby time - Fuel consumption - Work efficiency variation

Observation Results:

Site A (road construction): - Excavator utilization: 58% (standby time 42%) - Standby reasons: Waiting for dump truck arrival (26%), operator breaks (16%) - Veteran vs. novice efficiency difference: 30%

Site B (land development): - Excavator utilization: 72% - Fuel consumption: 18% less than Site A (veteran operator) - Excavation precision: Veterans achieve proper depth in one go, novices adjust repeatedly

Site C (demolition): - Excavator utilization: 45% (lowest) - Standby reason: Waiting for next work instructions (35%) - Operator feedback: "Spend long time searching for site supervisor to know what to excavate"

Phase 2: Orient (2 days)

From observed information, we narrowed AI utilization focus.

Judgment 1: Biggest issue is "standby time" - Average utilization: 58% - Standby time: 42% (42% of annual work hours wasted) - Calculation: Reducing standby time 20% enables $700,000 annual cost reduction

Judgment 2: Veteran know-how is person-dependent - Veteran-novice efficiency difference: 30% - Veteran retirement advancing (average age 58) - Risk of know-how loss

Judgment 3: AI Utilization Direction - Focus: "Utilization improvement" and "know-how succession" - Specifically: 1. Predict and reduce standby time 2. AI learns veteran operation patterns

Phase 3: Decide (1 day)

We decided to "test small" rather than perfect plans.

Decision: Minimal pilot experiment - Target: Site A (road construction), 1 excavator - Duration: 4 weeks - Investment: Sensor installation + data collection tool = $15,000 - Goal: "Visualize standby time" (not yet using AI)

Phase 4: Act (4 weeks)

We immediately executed the decision.

Implementation Content: - Install sensors on excavator (record operation/stop) - Record operator operation logs - Record location information via GPS - 4 weeks of data collection

Discoveries After 4 Weeks:

Detailed Standby Time Analysis: - Dump truck arrival waiting: 26% (as expected) - Next work instruction waiting: 12% (more than expected) - Operator breaks: 16% (as expected) - Unexpected discovery: Equipment "slight waiting" 4% - Judgment "almost finished, so wait for next truck" - Actually, moving to next location more efficient

Veteran Operation Patterns: - Constant excavation speed (novices have unstable speed) - Arm angle optimized - Reason for 18% better fuel efficiency became visible numerically

Chapter 4: Loops 2-4 — Accelerating Observe-Orient-Decide-Act

Loop 2: AI Prediction Introduction (6 weeks)

Observe: - Analyzed data collected in Loop 1 - Discovered regularity in dump truck arrival patterns

Orient: - If AI can predict dump truck arrival, can reduce standby time

Decide: - Trial AI prediction system introduction (1 site, budget $29,200)

Act: - AI predicts dump truck arrival times - Notifies operator "arriving in 3 minutes" - Reallocates standby time to other work

Result: - Standby time (dump waiting): 26% → 8% (69% reduction) - Utilization: 58% → 76%

Loop 3: AI-ifying Veteran Know-How (8 weeks)

Observe: - Detailed analysis of veteran operation pattern data - Quantified optimal excavation angle, speed, timing

Orient: - Presenting this optimal pattern to novices improves efficiency

Decide: - AI operation support system development

Act: - Real-time display of "optimal angle" and "optimal speed" on novice operators' operation screens - Instructions like "Lower arm 5 degrees now"

Result: - Novice work efficiency: 70% of veteran → 88% - Fuel consumption: 12% reduction - Novice feedback: "Game-like understanding of optimal operations"

Loop 4: Company-Wide Deployment Judgment (12 weeks)

Observe: - Pilot complete at 3 sites - All achieved 15-20% utilization improvement - ROI: Investment recovery period 6.2 months

Orient: - Technically feasible, economically rational - Ready for company-wide deployment

Decide: - Decision to deploy to all owned construction equipment (520 units)

Act: - 3-year phased implementation plan - Year 1: 100 units, Year 2: 200 units, Year 3: 220 units

Comprehensive Results After 12 Months:

Implementation Record: - AI-equipped machinery: 120 units (on schedule) - Utilization: 58% → Average 74% (16-point improvement) - Fuel reduction: Average 10% - Annual cost reduction: $2.67 million

Organizational Change: - "Plan before moving" → "Learn while moving" culture - OODA loop standardization (standard process for new technology introduction) - AI specialist team established (5 members)

Customer Value Delivery: - Proposal to rental customers: "AI-equipped equipment has high utilization" - New service: Operation data analysis service (subscription) - Differentiation: AI features competitors lack

Phase 5: Next Challenge (Ongoing)

OODA loops never end. Next observations had begun.

New Observe: - From AI-accumulated data, discovered "failure precursor" patterns - Next loop: Predictive maintenance system development

Final Results After 24 Months:

Business Metrics: - Annual revenue: $317M → $354M (+12%) - AI-related service revenue: New $10M - Customer satisfaction: 3.8 → 4.6 - Competitive advantage: "AI construction equipment leading company"

AI Implementation Expansion: - Equipped machinery: 520 units (all complete) - Utilization: Average 78% - Cumulative cost reduction: $7.08M annually - New features: Predictive maintenance, automatic reporting, remote monitoring

Customer Testimonials:

Construction Company - Engineering Manager: "BuildMach's AI construction equipment has overwhelmingly high utilization. Previously, actual work was 5 hours of 8-hour days. Now it's 7 hours. Construction periods shortened, costs decreased."

Operator (28): "Even as a novice, AI support enables veteran-level work. It guides 'a bit more left,' reducing failures."

Chapter 5: The Detective's OODA Diagnosis — Technology for Making Uncertainty an Ally

Holmes compiled the comprehensive analysis.

"Mr. Yamada, OODA's essence is 'adaptation.' In uncertain worlds, perfect plans can't be created. Observe, orient, decide, act. Then observe the results again. This high-speed loop is the only way to survive a rapidly changing era."

Final Report 36 Months Later:

BuildMach established a new position as "AI/IoT innovator" in the construction machinery industry.

Final Results: - Annual revenue: $317M → $433M (+37%) - AI/IoT-related revenue: $10M → $40M - Operating profit margin: 8% → 15% - Industry award: "Most innovative construction equipment manufacturer"

Yamada's letter expressed deep gratitude:

"Through OODA, we transformed from 'a planning organization' to 'an adapting organization.' Most important was understanding 'we don't need to create perfect plans.' Observe small, judge quickly, act immediately. This repetition produced far more than a year of planning meetings. Now all new technology introductions proceed with OODA. We understand that uncertainty is not an enemy but a learning opportunity."

The Detective's Perspective — Plans Are Comfort, Adaptation Is Growth

That night, I reflected on how to face uncertainty.

OODA's true value lies in courage. Creating perfect plans brings comfort. But in uncertain worlds, that comfort is illusion. While creating plans, the world changes.

Observe, orient, decide, act. Then fail. But learn from that failure and observe again. Only this repetition is the path to advance in a changing world.

"Those who stand still with perfect maps go less far than those who walk with imperfect compasses."

The next case will also depict a moment when OODA thinking carves out a company's future.

"In uncertain worlds, plans provide comfort but don't advance. Only repetition of observation and action carves the future."—From the detective's notes

Related files

Solve Your Business Challenges with Kindle Unlimited!

Access millions of books with unlimited reading.

Read the latest from ROI Detective Agency now!

*Free trial available for eligible customers only