ROI Case File No.300 | 'EcoWaste's Escape from Chaos'

📅 2025-11-06 11:00

🕒 Reading time: 8 min

🏷️ OODA

- Chapter One: New System Nightmare—Gap Between Ideal and Reality

- Chapter Two: Planning's Limit—Control Uncertain Field Through Adaptation

- Chapter Three: Descent to Field—52 Truths Observation Reveals

- Chapter Four: High-Speed Loop Chain—Adaptation Every 2 Weeks

- Chapter Five: Detective's Diagnosis—Volume 24 Conclusion, Journey of Reproducibility

- Related files

Chapter One: New System Nightmare—Gap Between Ideal and Reality

The week after Metalix's PPM case was resolved, a consultation arrived from Chiba regarding a waste management company's system operation. Episode 300, the final episode of Volume 24 "Proof of Reproducibility," is a story where not perfect planning but adaptability staying close to the field converges chaos.

"Detective, we introduced a new workflow system. Three months ago. But the field is in complete chaos. Complaints of 'can't use,' 'too complex' arrive daily. Modification requests exceed 50 items. I don't know where to start anymore..."

Shinji Yamamoto, information systems section chief at EcoWaste, a native of Chiba, visited 221B Baker Street with a completely exhausted expression. In his hands were system manuals and, in stark contrast, photos of whiteboards with massive sticky notes labeled "Modification Request."

"We handle industrial waste collection and processing in Chiba. 45 collection staff, 28 processing facility operators. In March 2025, we introduced a new system to streamline business flow. But the field can't master it."

EcoWaste's Post-System Implementation Chaos: - Founded: 2008 (industrial waste processing) - Annual revenue: ¥1.8 billion - Employees: 73 - New system: Operation started March 2025 - Implementation cost: ¥42 million - Current status: 35% utilization rate (65% concurrent old method) - Modification requests: 52 items (3 months) - Maintenance/modification cost: Monthly average ¥1.8M (3x expected)

There was deep regret in Yamamoto's voice.

"Pre-implementation seemed perfect. Vendor demo was excellent. I was convinced 'we can streamline with this.' But the moment we put it in the field, everything went wrong. Staff say 'the old way was better.' Modification requests increase daily. I don't know what's correct anymore."

Typical Chaos Cases:

Collection Staff's Scream: "Collection routes displayed on tablet differ from actual roads. Instructions to drive large trucks through narrow alleys. We manually correct on-site every time. Paper maps were faster."

Processing Facility Operator's Scream: "Processing record input screen is complex. Previously just 3 items, now 12. Moreover, too many required fields, so we enter 'Unknown' for items we don't know. Data meaningless."

Office Staff's Scream: "System is heavy, screen switching takes 10 seconds. Processing 200 slips daily, so waiting time alone is 30 minutes. Old system was 2 seconds."

Partial Modification Requests (of 52): 1. Match collection route map to actual roads 2. Reduce processing record input items 3. Improve screen display speed 4. Review required fields 5. Make smartphone-compatible ... (47 more items)

"Vendor says 'as specified.' But field says 'can't use.' We don't have budget or time to respond to all modifications."

Chapter Two: Planning's Limit—Control Uncertain Field Through Adaptation

"Mr. Yamamoto, how was pre-implementation requirements definition conducted?"

To my question, Yamamoto answered.

"Meticulously. Spent half a year interviewing the field, extracting requirements. Had many meetings with vendor. Should have been perfect planning but..."

Pre-Implementation Approach (Planning-Focused): - Requirements definition: 6 months - Development period: 9 months - Testing: 2 months - Premise: "Success if create perfect plan" - Result: Diverged from field reality

I explained the importance of adaptive approach.

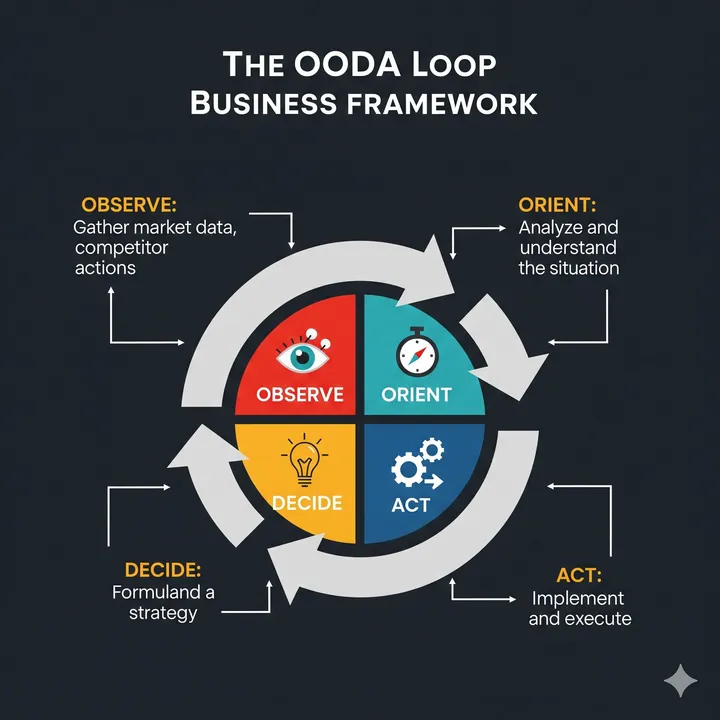

"Perfect planning collapses before post-operation reality. OODA—Observe, Orient, Decide, Act. Not planning, but observe the field and immediately adapt. This high-speed loop transforms chaos into order."

⬜️ ChatGPT | Catalyst of Conception

"Planning collapses in field. With OODA, observe, judge, immediately move"

🟧 Claude | Alchemist of Narrative

"Perfect blueprints are illusions. Fields are unpredictable. Only adaptation converges chaos"

🟦 Gemini | Compass of Reason

"OODA is immediate response technology. Cycle Observe, Orient, Decide, Act at high speed, follow reality"

The three team members began analysis. Gemini deployed the "OODA Loop Framework" on the whiteboard.

OODA Loop's 4 Steps: 1. Observe: Observe field reality 2. Orient: Analyze information, judge situation 3. Decide: Decide next action 4. Act: Execute immediately

"Mr. Yamamoto, let's converge EcoWaste's system chaos with OODA Loop."

Chapter Three: Descent to Field—52 Truths Observation Reveals

Phase 1: Observe (1 week)

Yamamoto himself entered the field for thorough observation.

Collection Field (Truck ride-along, 3 days):

Observation 1: Route Problem - System-shown route: Calculated as shortest distance - Reality: Shortest route impassable due to one-way streets, height restrictions - Staff behavior: Search for detour routes manually every time - Time required: Daily average +45 minutes

Observation 2: Tablet Operability - System: Small screen, difficult-to-read text - Reality: Operated in passenger seat while truck driving (shaking) - Staff behavior: Frequent mistaps, irritation - Real feelings: "Paper was easier to see"

Processing Facility (Operator work observation, 2 days):

Observation 3: Input Item Problem - System: 12 items detailed records (ideal is accurate data) - Reality: Operators visually judge waste type, details unknown - Staff behavior: Enter "Unknown" for unknown items - Result: Data inaccurate, unusable for analysis

Observation 4: Screen Heaviness - System: High-function, multi-function - Reality: Processing facility tablets are 3-year-old legacy models - Staff behavior: Wait 10 seconds each screen switch - Real feelings: "Irritated, skip input"

Office (Slip processing observation, 2 days):

Observation 5: Approval Flow Problem - System: 3-stage approval (Staff→Section chief→Manager) - Reality: Section chief and manager out, approval delayed - Staff behavior: Work stops waiting for approval - Real feelings: "Could process with staff judgment before"

Phase 2: Orient (2 days)

Analyzed observation results, set priorities.

Classify 52 modification requests into 3:

Urgent (Leads to work stoppage): 1. Collection route correction: Remove impassable routes (10 items) 2. Screen display speed improvement: Tablet compatible (8 items) 3. Approval flow simplification: Expand staff authority (6 items)

Important (Efficiency decline): 4. Input item reduction: Narrow required items to 3 (12 items) 5. Tablet UI improvement: Enlarge text size (9 items)

Improvement (Nice to have): 6. Other feature additions (7 items)

Judgment: Not respond to all 52 items, focus on Urgent and Important.

Phase 3: Decide (1 day)

Immediately decided high-priority modifications.

1st Modification (Emergency Response): - Target: 24 urgent items - Period: 2 weeks - Cost: ¥2.8M - Policy: Aim for "field can use from today" state

Phase 4: Act (2 weeks)

Immediately executed decision.

Modification Content:

1. Collection Route Correction (1 week): - Corrected system route data to actual road conditions - Reflected one-way streets, height restrictions, width restrictions - Verified by actually driving with field staff

2. Screen Display Speed Improvement (1 week): - Lightened screen to match tablet specs - Removed unnecessary images and animations - Display speed: 10 seconds → 2 seconds

3. Approval Flow Simplification (3 days): - Granted staff decision authority up to certain amount (under ¥300K) - Changed section chief and manager approval to post-reporting

Chapter Four: High-Speed Loop Chain—Adaptation Every 2 Weeks

Results After 1st Modification (2 weeks later):

Utilization Rate: - 35% → 68% (+33 points)

Field Voices: - Collection staff: "Routes became accurate. Don't get lost" - Operators: "Screen got faster, stress reduced" - Office staff: "Approval waiting gone"

However, dissatisfaction still remained.

2nd OODA Loop (2 weeks later):

Observe: - Utilization rate increased but still 32% concurrent old method - New observation: Too many input items stands out

Orient: - Of 12 input items, only 4 actually used - Remaining 8 filled with "Unknown" or "Other"

Decide: - Reduce input items to 4 - Detailed data can be added later as needed

Act (1 week): - Simplified input screen - Required items: Only 4

Results: - Input time: 5 minutes per case → 1.5 minutes (70% reduction) - Utilization rate: 68% → 85%

3rd OODA Loop (4 weeks later):

Observe: - Many tablet touch operation mistakes (truck shaking) - Voices hoping for voice input

Orient: - Staff average age: 48 - Voice input easier than touch operation

Decide: - Add voice input function

Act (2 weeks): - Input complete just by saying "Milk cartons, 50kg"

Results: - Utilization rate: 85% → 96% - Collection staff satisfaction: 3.2 → 4.6

4th OODA Loop (6 weeks later):

Observe: - System stable, no major dissatisfaction - But data analysis function unused

Orient: - Management "don't know what to analyze" - Data exists but not utilized

Decide: - Add monthly report auto-generation function

Act (2 weeks): - Automatically graph collection efficiency, processing volume, costs, etc.

Results: - Data utilization: Zero → Used in monthly meetings - Management decision accuracy improved

Chapter Five: Detective's Diagnosis—Volume 24 Conclusion, Journey of Reproducibility

Final Results After 6 Months:

Utilization Rate: - 35% → 98%

Business Efficiency: - Collection work: +2.5 hours daily efficiency - Processing records: 70% input time reduction - Slip processing: Zero approval waiting time

Cost: - Modification costs (6 months): Cumulative ¥8.2M - Deletion through efficiency: ¥3.2M monthly - Payback period: 2.6 months

Organizational Change: - System department: "Planner" → "Companion" - Field staff: "Resistance" → "Cooperation" - Bi-weekly OODA review meetings became regular

That night, Holmes reflected on Volume 24.

"Mr. Yamamoto, OODA's essence is 'humility.' We can't perfectly predict the future. Perfect planning doesn't exist. So we observe, judge, decide, act. And observe again. Only this high-speed loop controls uncertain fields."

Volume 24 "Proof of Reproducibility" concludes here.

5WHYS, VRIO, DESC, EMPATHY, 4P, Logic Tree, KPT, BSC, PPM, and OODA.

Through 10 cases, we confirmed one truth again.

Business success is reproducible.

Problems have structure. Frameworks exist to perceive that structure. And if one masters those frameworks, anyone can reproduce the same results.

The 10 frameworks learned in Volume 24 each address different problems. But common to all is "structuring."

Structure chaos, decompose problems into elements, clarify causal relationships. Then take appropriate action.

"Reproducibility is technology that transforms chaos into order. And that technology can be mastered by anyone"

Volume 24 concludes here.

But the detective's journey doesn't end. In the next volume, we'll step into even deeper realms of reproducibility.

"Perfect planning is illusion. Observe the field, immediately adapt. Only OODA's high-speed loop controls the uncertain world"—From the detective's notebook

— Volume 24 "Proof of Reproducibility" END —

Related files

🎖️ Top 3 Weekly Ranking of Case Files

'Tech Innovators' Loss Through Rework'

'PharmaLogistics' Invisible Customer'

'UrbanDesign's Blueprint Labyrinth'