ROI Case File No.316 | 'Marukyu's Unstoppable Improvement'

📅 2025-11-14 11:00

🕒 Reading time: 10 min

🏷️ PDCA

- Chapter 1: The Contradiction of Inventory—Nothing That Sells, Overflowing with What Doesn't

- Chapter 2: The Illusion of Intuition—No Improvement Without Cycling the Plan

- Chapter 3: First Cycle—Rotate Small, Learn Fast

- Chapter 4: Second and Third Cycles—Rotation Changes the Organization

- Chapter 5: The Result of Circulation—Organizational Change After 12 Months

- Chapter 5: The Detective's Diagnosis—Improvement Deteriorates the Moment It Stops

- Related Files

Chapter 1: The Contradiction of Inventory—Nothing That Sells, Overflowing with What Doesn't

The week after MDF's SWOT case was resolved, a consultation arrived from Tokyo regarding inventory management at a sports retail company. Case File 316 of Volume 26, "The Pursuit of Reproducibility," tells the story of optimizing inventory not by stopping after one improvement, but by continuing rotation.

"Detective, we're facing a serious inventory problem. Popular products are constantly out of stock. Every day we apologize to customers: 'We're sorry, it's sold out.' Meanwhile, the warehouse is piled high with products from 3 years ago. 12 million yen in dead inventory annually. This repeats every year."

Kenta Maruyama, Merchandise Manager of Marukyu Sports Co., born in Koto Ward, visited 221B Baker Street with exhaustion written across his face. In his hands were a stockout product list and a dead inventory list. Both lists were about the same thickness.

"We're a sports goods retailer in Tokyo, established 52 years ago. We have 5 stores and also operate EC business. Running shoes, wear, training equipment... we handle about 3,200 SKUs. However, inventory management has collapsed."

Marukyu's Inventory Crisis: - Established: 1973 (sports goods retail) - Annual Revenue: 1.8 billion yen (stores 1.2B, EC 600M) - Number of Stores: 5 - SKU Count: About 3,200 - Inventory Turnover Rate: 2.8 times/year (industry average 4.5 times) - Stockout Rate: Monthly average 18% (opportunity loss on popular products) - Dead Inventory: 12 million yen annually (occupies 32% of warehouse) - Problem: Demand forecasting depends on staff intuition, data analysis system not established

Maruyama's voice carried deep anxiety.

"The problem is we don't know what to order. Staff order based on intuition: 'This sold well last year.' But trends change yearly. Last year's bulk purchase becomes this year's dead inventory. Meanwhile, products that go viral on SNS sell out instantly. Even if we reorder, delivery takes 2 months. Customers won't wait."

Typical Inventory Problem Example:

Fall/Winter 2024 Season:

Popular Product A Stockout: - Product Name: "Nike Air Zoom Pegasus 40" (running shoes) - Order: September 1, 100 pairs - Arrival: September 15 - Sales: Sold out September 15-28 (2 weeks) - Reorder: September 28, 150 pairs - Expected Arrival: November 28 (2 months later) - Result: Stockout for 2 months, October-November

Maruyama: "We get 10 daily inquiries from customers asking 'Do you have stock?' All we can do is apologize. Estimated opportunity loss is 3 million yen."

Meanwhile, Dead Inventory B: - Product Name: "Adidas Ultraboost 22" (running shoes) - Order: September 2022, 200 pairs - Sales Performance: 48 pairs in 2 years (24%) - Remaining Inventory: 152 pairs (sleeping in warehouse) - Purchase Cost: 12,000 yen per pair - Inventory Value: 1.82 million yen - Discount Sales: Won't sell even at 50% OFF

Maruyama: "Two years ago, I thought 'This will definitely sell' and ordered 200 pairs. But it didn't sell. Now it's warehouse fertilizer."

Chapter 2: The Illusion of Intuition—No Improvement Without Cycling the Plan

"Maruyama-san, how is the current purchase plan established?"

To my question, Maruyama answered.

"Three months before season start, staff decide 'how many of this product to order.' Based on past sales performance and staff intuition. But we don't review afterward. Even if sales trends change during the season, we don't modify the plan."

Current Approach (Fixed Plan Type): - Purchase Plan: Established only once before season - Assumption: "Things will proceed according to plan" - Problem: Don't correct even when plan and reality diverge

I explained the importance of continuing the improvement cycle.

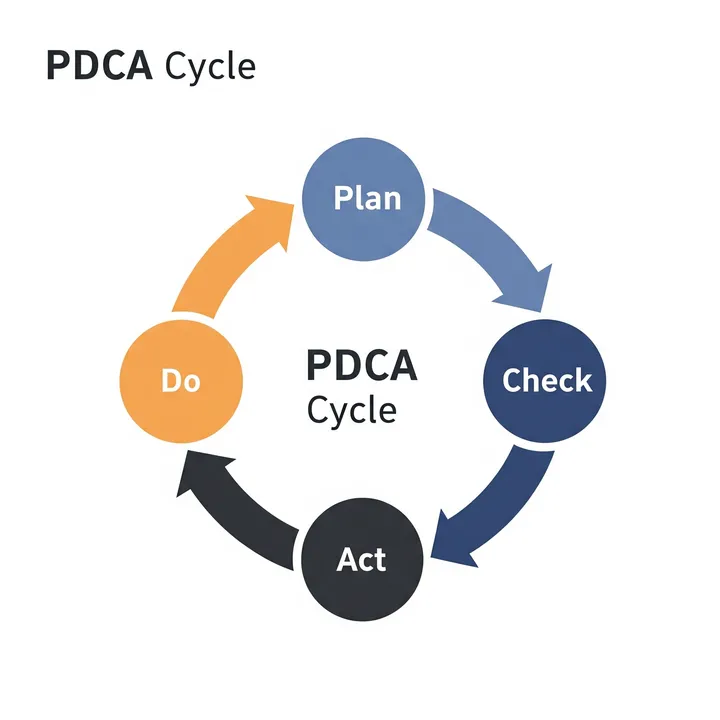

"Plans collapse before reality. PDCA—Plan, Do, Check, Act. Plan, execute, evaluate, improve. Not stopping this cycle is the essence of inventory optimization."

⬜️ ChatGPT | Catalyst of Conception

"Don't stop after making a plan. Cycle with PDCA. Improvement doesn't end in one rotation."

🟧 Claude | Alchemist of Narrative

"Inventory is alive. The moment it stops, it rots. PDCA creates circulation."

🟦 Gemini | Compass of Reason

"PDCA is circulation technology. Cycle Plan-Do-Check-Act at high speed to follow reality."

The three members began their analysis. Gemini unfolded the "PDCA Framework" on the whiteboard.

PDCA's 4 Steps: 1. Plan: Plan replenishment cycle from sales history 2. Do: Order based on plan 3. Check: Visualize inventory turnover rate and stockout rate weekly 4. Act: Implement SKU-specific adjustments each season

"Maruyama-san, let's rebuild Marukyu's inventory management with PDCA."

Chapter 3: First Cycle—Rotate Small, Learn Fast

Phase 1: Plan - First Cycle (2 weeks)

First, we analyzed 3 years of sales data.

Analysis Target: - 3,200 SKUs × 3 years of sales performance - Seasonal variations, trends, store-specific sales

Findings:

1. ABC Analysis (Sales Contribution Classification): - A Rank (top 20%): 68% of sales (640 SKUs) - B Rank (middle 30%): 22% of sales (960 SKUs) - C Rank (bottom 50%): 10% of sales (1,600 SKUs)

2. Seasonal Variations: - Running shoes: Peak in spring (April-June), fall (September-November) - Wear: Peak in summer (July-August), winter (December-February) - Training equipment: Stable year-round

3. Inventory Turnover Rate: - A Rank: 6.8 times/year (good) - B Rank: 3.2 times/year (somewhat low) - C Rank: 0.9 times/year (very low, becoming dead inventory)

First Cycle Plan: - Target: A Rank products only (640 SKUs) - Goal: Inventory turnover rate 6.8 times → 9.0 times - Order Cycle: Monthly → Weekly - Safety Stock: 2 weeks' worth (was 2 months)

Phase 2: Do - First Cycle (1 month)

Based on the plan, we made A Rank product orders weekly.

New Order Flow:

Conventional (Monthly Orders): - Bulk order for one month at start of month - Arrival: Mid-month - Problem: Stockout by month end, or excess inventory at month end

New Orders (Weekly Orders): - Order 1 week's worth every Monday - Arrival: Next Monday (7-day lead time) - Inventory: Always maintain 2 weeks' worth

Negotiation with Manufacturers: "Please allow us to order small lots weekly" → Relaxed minimum order quantities, enabling weekly orders

Phase 3: Check - First Cycle (After 1 month)

After 1 month, we evaluated results.

A Rank Products (640 SKUs) Results: - Inventory turnover rate: 6.8 times/year → 10.2 times/year (+50%) - Stockout rate: 18% → 8% (56% reduction) - Inventory value: 48 million yen → 32 million yen (33% reduction)

Specific Example: Nike Air Zoom Pegasus 40 - Conventional: Order 100 pairs monthly → Sold out in 2 weeks → 2 weeks stockout - New Method: Order 25 pairs weekly → Always in stock - Stockout rate: 50% → 2% - Sales: 2 million yen/month → 3.8 million yen/month (+90%)

Maruyama was astonished.

"Just by ordering weekly, it changes this much...?"

Phase 4: Act - First Cycle (1 week)

Based on evaluation results, we decided improvement points for the next cycle.

Improvement Points: 1. Insufficient response to seasonal variations → Increase safety stock 1.5x before spring/fall peaks 2. Not considering store-by-store sales differences → Adjust order quantities by store 3. B and C Rank products not addressed → Start with B Rank in second cycle

Chapter 4: Second and Third Cycles—Rotation Changes the Organization

Second Cycle (Month 2):

Plan: - Target: A Rank (continue) + Add B Rank products (960 SKUs) - A Rank improvement: Reflect seasonal variations, store-specific adjustments

Do: - Shift B Rank products to weekly orders too

Check (After 2 months): - A Rank inventory turnover: 10.2 times → 11.8 times (further improvement) - B Rank inventory turnover: 3.2 times → 5.6 times (+75%) - Overall stockout rate: 8% → 5%

Act: - Consider inventory reduction for C Rank products - Decide disposal policy for dead inventory

Third Cycle (Month 3):

Plan: - Organize C Rank products (1,600 SKUs) - Identify products not sold in past year (480 SKUs) - Disposal policy: 50% OFF sale, if still unsold, discard

Do: - C Rank 480 SKUs disposal sale - Stop future ordering

Check (After 3 months): - Disposal rate: 68% (326 SKUs disposal completed) - Warehouse occupancy: 32% → 18% (44% reduction) - Dead inventory value: 12 million yen → 4.2 million yen (65% reduction)

Act: - Continue disposal of remaining 154 SKUs - New orders only for SKUs with sales performance in past 3 months

Phase 5: Automatic Order System Implementation (Month 6)

After 3 PDCA rotations, success patterns became visible. We automated them.

Automatic Order System Implementation: - Investment: 6 million yen system development - Functions: - Demand forecasting from past sales history - Automatic ordering when inventory falls below safety stock - Consider seasonal variations, trends, store-specific factors - Target: A and B Rank products (1,600 SKUs)

After 6 months: - Order work hours: 20 hours/week → 2 hours/week (90% reduction) - Inventory turnover rate: 2.8 times/year → 8.4 times/year (+200%)

Chapter 5: The Result of Circulation—Organizational Change After 12 Months

Comprehensive Results After 12 Months:

Dramatic Improvement in Inventory Metrics: - Inventory turnover rate: 2.8 times/year → 8.4 times/year (+200%) - Stockout rate: 18% → 3% (83% reduction) - Dead inventory: 12 million yen → 2.8 million yen (77% reduction) - Warehouse occupancy: 100% → 52% (space available)

Financial Results: - Annual sales: 1.8 billion yen → 2.2 billion yen (+22%) - Reduced opportunity loss from stockouts - Increased sales of popular products - Inventory value: 120 million yen → 72 million yen (40% reduction) - Cash flow improvement: 48 million yen (inventory reduction effect) - Investment recovery period: 3.8 months

Organizational Change:

Weekly PDCA Meeting Established: - Every Monday, 30 minutes - Check inventory turnover rate, stockout rate on dashboard - Decide improvement points immediately

Maruyama's Reflection:

"Previously, we made a plan before season start and that was it. We thought 'things should proceed according to plan.' But reality doesn't proceed according to plan.

By introducing PDCA, a culture was born: 'Plans are hypotheses, verify with reality, improve.' The first month was hard. But as we cycled through the second and third months, improvement points became visible.

Now it's normal to discuss 'how to improve this week' in weekly meetings. PDCA must not be stopped after once. I understood that continuing to cycle is evolution."

Store Staff Voices:

Store Manager A: "Previously, every day was apologizing to customers: 'We're sorry, it's sold out.' Now popular products are always in stock. Being able to say 'We have it in stock' makes me so happy..."

Salesperson B: "The warehouse became spacious. Before, products from 3 years ago were piled up, with no space for new products. Now there's space available."

Executive Evaluation:

President: "I thought inventory management was something you do once and finish. But by cycling weekly with PDCA, it continues to be optimized constantly.

What particularly surprised me was cash flow. With 48 million yen inventory reduction, cash flow improved dramatically. With those funds, we're planning new store openings."

Chapter 5: The Detective's Diagnosis—Improvement Deteriorates the Moment It Stops

That night, I contemplated the essence of PDCA.

Marukyu thought that once they made a plan, that was the end. However, reality doesn't proceed according to plan.

By continuing weekly PDCA cycles, inventory continued to be optimized. The first cycle improved A Rank, the second expanded to B Rank, the third organized C Rank. And in the sixth month, they automated.

"Improvement doesn't end in one rotation. Continuing to cycle is evolution. PDCA creates unstoppable improvement."

The next case will also depict the moment when PDCA creates circulation.

"Don't stop after making a plan. Cycle weekly. Plan-Do-Check-Act. The moment rotation stops, inventory rots"—From the Detective's Notes

Related Files

🎖️ Top 3 Weekly Ranking of Classified Case Files

What is ROI

What is STP Analysis

What is the RICE Framework