ROI Case File No.367 | 'OptiData's Handwritten Text Barrier'

📅 2025-12-28 23:00

🕒 Reading time: 12 min

🏷️ BSC

- Chapter 1: Paper-Based Relic — 960 Hours Monthly Manual Entry Hell

- Chapter 2: One-Dimensional OCR Implementation Decision — Four Perspectives Invisible

- Chapter 3: Phase 1 — Multifaceted Evaluation Through BSC

- Chapter 4: Phase 2 — OCR + RPA Integrated Solution Implementation

- Chapter 5: Detective's Diagnosis — Multifaceted Evaluation Through BSC

- Related Files

Chapter 1: Paper-Based Relic — 960 Hours Monthly Manual Entry Hell

The day after resolving Globex Corporation's MANDALA case, a consultation arrived regarding paper document digitalization. Volume 29, "The Pursuit of Reproducibility," Case 367 tells the story of discovering overall optimization from four perspectives.

"Detective, our factory is paper hell. Receiving slips, shipping slips, quality inspection sheets. All paper. And we manually transcribe into the system. We spend 960 hours monthly. Handwritten text misreadings frequently occur. We want to implement OCR, but we're uncertain whether it will truly be effective."

Kenichi Suzuki, Operational Improvement Director of OptiData, an Ibaraki native, visited 221B Baker Street with an exhausted expression. In his hands, he held bundles of handwritten slips, contrasting sharply with the latest OCR proposal document titled "OCR Solution Proposal with RPA Integration 2025."

"We manufacture industrial sensors. 180 employees. Annual revenue of 4.2 billion yen. Ibaraki factory is our main base. However, paper-based operations are inefficient. We implemented NTT's WinActor in fiscal 2025, but it's not integrated with OCR."

OptiData's Current State: - Founded: 1988 (Industrial sensor manufacturing) - Employees: 180 (120 at Ibaraki factory) - Annual Revenue: 4.2 billion yen - Issues: Paper-based document manual entry, handwritten text reading difficulty, RPA alone has limits

Deep anxiety resonated in Suzuki's voice.

"The breakdown of paper documents at Ibaraki factory is as follows. First, receiving slips. When parts are delivered from suppliers, paper slips are attached. 600 cases monthly. Part numbers, quantities, lot numbers are handwritten. We manually transcribe these into the system. 5 minutes per case. Takes 50 hours monthly.

Next, shipping slips. When shipping products to customers, we create paper slips. 800 cases monthly. We handwrite product names, quantities, shipping destinations. We also manually transcribe these into the system. 6 minutes per case. Takes 80 hours monthly.

Finally, quality inspection sheets. We record product quality inspection results handwritten on paper. 1,200 cases monthly. We handwrite 10 inspection items. We also manually transcribe these into the system. 10 minutes per case. Takes 200 hours monthly."

Manual Entry Work Reality for Paper Documents:

Receiving Slips (600 cases/month): - Items: Supplier name, part number, quantity, lot number, delivery date - Handwritten rate: 80% (suppliers handwrite) - Manual entry time: 5 min/case - Monthly hours: 600 cases × 5 min = 50 hours/month - Personnel: 3 receiving staff

Shipping Slips (800 cases/month): - Items: Customer name, product name, quantity, shipping date, shipping address - Handwritten rate: 100% (handwritten in-house) - Manual entry time: 6 min/case - Monthly hours: 800 cases × 6 min = 80 hours/month - Personnel: 4 shipping staff

Quality Inspection Sheets (1,200 cases/month): - Items: Product name, lot number, 10 inspection items (pass/fail), inspector name - Handwritten rate: 100% (inspectors handwrite) - Manual entry time: 10 min/case - Monthly hours: 1,200 cases × 10 min = 200 hours/month - Personnel: 5 quality control staff

Total Monthly Manual Entry Hours: 330 hours/month Annual Manual Entry Hours: 3,960 hours/year

Suzuki sighed deeply.

"There's another problem. Handwritten text misreadings. Misreading part numbers on receiving slips and ordering wrong parts occurs 3 times monthly. Misreading numbers on quality inspection sheets and shipping defective products occurred twice annually.

WinActor is already implemented, but without OCR, it cannot read paper documents. We're only automating copy-and-paste work on Excel data. I've heard that integrating with OCR enables automatic processing of paper documents, but will it truly be effective?"

Chapter 2: One-Dimensional OCR Implementation Decision — Four Perspectives Invisible

"Mr. Suzuki, do you believe implementing OCR will solve all problems?"

Suzuki showed a confused expression at my question.

"Yes, I believe OCR reading of paper documents eliminates manual entry. However, I cannot see whether it will truly be effective or the return on investment."

Current Understanding (Technology Implementation Model): - Expectation: OCR implementation reduces manual entry - Problem: Company-wide perspective remains invisible

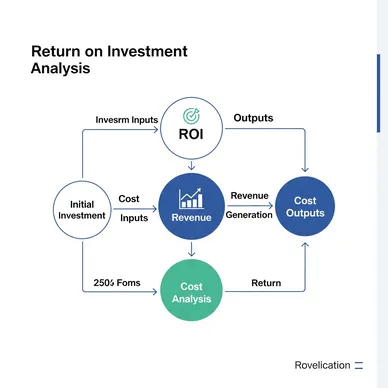

I explained the importance of discovering overall optimization from four perspectives.

"The problem is the one-dimensional decision to 'implement OCR.' BSC—Balanced Scorecard. Financial, customer, business process, learning and growth. We evaluate from these four perspectives and establish balanced strategy. Reproducible automation emerges from multifaceted evaluation."

⬜️ ChatGPT | Catalyst of Conception

"Don't judge one-dimensionally. Evaluate from BSC's four perspectives: financial, customer, process, growth"

🟧 Claude | Alchemist of Narrative

"Paper is always 'memory of the past.' Transforming it to digital opens the future"

🟦 Gemini | Compass of Reason

"Evaluate through BSC. Financial perspective, customer perspective, business process perspective, learning and growth perspective. When four align, overall optimization becomes visible"

The three members began analysis. Gemini developed the "BSC Framework" on the whiteboard.

BSC's Four Perspectives: 1. Financial Perspective: Will cost reduction and revenue increase be realized? 2. Customer Perspective: Will customer satisfaction and delivery compliance improve? 3. Business Process Perspective: Will operational efficiency and quality improvement be realized? 4. Learning and Growth Perspective: Will employee skill improvement and organizational capability improvement be realized?

"Mr. Suzuki, let's first evaluate OCR implementation from BSC's four perspectives."

Chapter 3: Phase 1 — Multifaceted Evaluation Through BSC

Step 1: Financial Perspective (2 weeks)

Current Cost Analysis:

Labor Cost (Manual Entry Work): - Monthly hours: 330 hours/month - Hourly wage: 3,200 yen (average) - Monthly labor cost: 330 hours × 3,200 yen = 1.056 million yen/month - Annual labor cost: 1.056 million × 12 months = 12.672 million yen/year

Loss From Erroneous Entry: - Receiving slip misreadings: 3 cases/month × 80,000 yen reorder cost = 240,000 yen/month - Quality inspection sheet misreadings: 2 cases/year × 1.5 million yen defective product recall cost = 3 million yen/year - Annual erroneous entry loss: 240,000 yen × 12 months + 3 million = 5.88 million yen/year

Annual Total Cost: - 12.672 million + 5.88 million = 18.552 million yen/year

Reduction Effect From OCR Implementation:

OCR Solution Selection: - Tool: AI-OCR "DX Suite" (handwritten text support) - Price: 150,000 yen/month (unlimited reading) - Initial implementation cost: 1.8 million yen (customization, WinActor integration)

Reduction Effect: - Manual entry time: 330 hours/month → 50 hours/month (85% reduction) - Time saved: 280 hours/month - Labor cost reduction: 280 hours × 3,200 yen = 896,000 yen/month = 10.752 million yen/year

Erroneous Entry Reduction: - OCR recognition accuracy: 98% (AI-OCR with handwritten text support) - Erroneous entry: 3 cases/month → 0.5 cases/month (83% reduction) - Erroneous entry loss reduction: 5.88 million × 83% = 4.88 million yen/year

Total Financial Effect: - 10.752 million + 4.88 million = 15.632 million yen/year

Investment: - Initial implementation cost: 1.8 million yen - Annual operation cost: 150,000 yen × 12 months = 1.8 million yen/year

ROI (First Year): - (15.632 million - 3.6 million) / 3.6 million × 100 = 334% - Payback period: 3.6 million ÷ 15.632 million = 0.23 years (2.8 months)

Financial Perspective: ◎ (High return on investment)

Step 2: Customer Perspective (2 weeks)

Current Customer Satisfaction:

Delivery Compliance Rate: - Target delivery: Within 10 days from order - Current: 12 days from order (average) - Delay reasons: Receiving slip manual entry delay, quality inspection sheet transcription delay

Customer Complaints: - Monthly complaints: 5 cases (3 delivery delays, 2 quality issues) - Quality issue cause: Quality inspection sheet transcription errors

Customer Value Improvement From OCR Implementation:

Delivery Shortening: - Receiving slip OCR reading: Immediate system reflection - Quality inspection sheet OCR reading: Immediate system reflection - Delivery: 12 days → 10 days (2 days shortened) - Delivery compliance rate: 78% → improved to 95%

Quality Improvement: - Quality inspection sheet transcription error reduction: 2 cases/month → 0.3 cases/month - Customer complaint reduction: 5 cases/month → 2 cases/month (60% reduction)

Customer Satisfaction Improvement: - Through delivery compliance rate improvement, customer satisfaction survey score: 7.2 points → 8.5 points (out of 10)

Customer Perspective: ◎ (High customer value improvement)

Step 3: Business Process Perspective (2 weeks)

Current Business Process:

Receiving Operations: 1. Parts delivered from supplier (paper slip attached) 2. Receiving staff confirms paper slip (5 min) 3. Manual system transcription (5 min) 4. Reflected in inventory system Total: 10 min/case

Business Process After OCR Implementation:

New Flow: 1. Parts delivered from supplier (paper slip attached) 2. Read paper slip with scanner (30 sec) 3. OCR automatically recognizes and transcribes to system (30 sec) 4. WinActor automatically reflects in inventory system (30 sec) 5. Human final confirmation (1 min) Total: 2.5 min/case

Before: 10 min/case After: 2.5 min/case Reduction rate: 75%

Quality Inspection Operations Efficiency:

Before: 1. Inspector conducts quality inspection (10 min) 2. Handwrite results on paper (3 min) 3. Quality control staff manually transcribes to system (10 min) Total: 23 min/case

After: 1. Inspector conducts quality inspection (10 min) 2. Handwrite results on paper (3 min) 3. OCR automatically recognizes and transcribes to system (1 min) 4. WinActor automatically sends defective product alert (30 sec) Total: 14.5 min/case

Before: 23 min/case After: 14.5 min/case Reduction rate: 37%

Business Process Perspective: ◎ (High operational efficiency)

Step 4: Learning and Growth Perspective (2 weeks)

Current Employee Skills:

Time Consumption on Simple Tasks: - Manual entry work: 330 hours monthly - 12 employees engaged in simple tasks

Employee Growth From OCR Implementation:

Skill Shift: - Manual entry work: 330 hours/month → 50 hours/month (280 hours reduction) - Shift reduced 280 hours to value-added operations - Data analysis: 80 hours/month - Quality improvement activities: 100 hours/month - Business process improvement: 100 hours/month

New Skill Acquisition: - OCR/RPA operation skills: 12 people acquire - Data analysis skills: 8 people acquire - Training time: 16 hours per person (2 days)

Employee Satisfaction Improvement: - Liberation from simple tasks improves job satisfaction - Employee satisfaction survey: 6.8 points → 7.9 points (out of 10)

Organizational Capability Improvement: - As successful digitalization case, expandable to other bases - DX personnel development (12 people)

Learning and Growth Perspective: ◎ (High organizational capability improvement)

BSC Evaluation Summary:

| Perspective | Evaluation | Main Effects |

|---|---|---|

| Financial | ◎ | Annual 15.632 million yen reduction, ROI 334% |

| Customer | ◎ | 2-day delivery shortening, customer satisfaction +1.3 points |

| Business Process | ◎ | 75% receiving operations shortening, 37% inspection operations shortening |

| Learning & Growth | ◎ | 12 DX personnel trained, employee satisfaction +1.1 points |

Overall Evaluation: High evaluation in all perspectives, should promote implementation

Chapter 4: Phase 2 — OCR + RPA Integrated Solution Implementation

Month 1-2: Implementation Preparation

System Configuration: - OCR: AI-OCR "DX Suite" - RPA: WinActor (existing) - Integration: Automatically pass OCR reading results to WinActor

Implementation Target: - Ibaraki factory receiving slips, shipping slips, quality inspection sheets

Equipment Investment: - Scanner purchase: 10 units × 80,000 yen = 800,000 yen - OCR license: 1.8 million yen initial implementation cost (including customization)

Month 3: Pilot Implementation (200 cases/month)

New Operations:

Receiving Operations: 1. Read paper slip with scanner 2. OCR recognizes part number, quantity, lot number 3. WinActor automatically registers in inventory system 4. Human final confirmation on screen

Pilot Results (200 cases): - OCR recognition accuracy: 97.5% (handwritten text) - Recognition errors: 5 cases (2.5%) → manually corrected by humans - Processing time: 200 cases × 2.5 min = 8.3 hours (Before: 33 hours) - Reduction rate: 75%

Month 4-6: Company-Wide Expansion (2,600 cases/month)

Expansion to All Slip Types: - Receiving slips: 600 cases/month - Shipping slips: 800 cases/month - Quality inspection sheets: 1,200 cases/month

Month 7: Company-Wide Effect Measurement

KPI 1: Manual Entry Time Reduction - Before: 330 hours/month - After: 50 hours/month (final confirmation only) - Reduction rate: 85% - Time saved: 280 hours/month

KPI 2: Erroneous Entry Reduction - Before: 5 cases/month (3 receiving, 2 inspection) - After: 0.8 cases/month - Reduction rate: 84%

KPI 3: Delivery Shortening - Before: 12 days from order - After: 10 days from order - Shortened: 2 days

KPI 4: Customer Satisfaction - Before: 7.2 points - After: 8.4 points - Improvement: +1.2 points

KPI 5: Employee Satisfaction - Before: 6.8 points - After: 7.8 points - Improvement: +1.0 points

Annual Effects:

Financial Effects: - Labor cost reduction: 280 hours/month × 12 months × 3,200 yen = 10.752 million yen/year - Erroneous entry loss reduction: 5.88 million × 84% = 4.94 million yen/year - Total: 15.692 million yen/year

Investment: - Initial investment: 1.8 million + 0.8 million = 2.6 million yen - Annual operation cost: 1.8 million yen

ROI (First Year): - (15.692 million - 4.4 million) / 4.4 million × 100 = 257% - Payback period: 4.4 million ÷ 15.692 million = 0.28 years (3.4 months)

2nd Year Onward: - Annual net effect: 15.692 million - 1.8 million = 13.892 million yen/year

Month 8-12: Horizontal Expansion Plan to Other Bases

Following Ibaraki Factory's Success: - Plan expansion to Kanagawa factory (60 employees) - Plan expansion to Osaka sales office (25 employees) - Company-wide OCR + RPA standardization

Chapter 5: Detective's Diagnosis — Multifaceted Evaluation Through BSC

That night, I contemplated the essence of BSC.

OptiData was about to make the one-dimensional decision to "implement OCR." However, technology implementation should not be evaluated solely by financial effects.

By evaluating from four perspectives through BSC—Balanced Scorecard—overall optimization became visible.

Financial perspective: Annual 15.692 million yen reduction, ROI 257%, payback period 3.4 months. Customer perspective: 2-day delivery shortening, customer satisfaction +1.2 points. Business process perspective: 75% receiving operations shortening, 37% inspection operations shortening. Learning and growth perspective: 12 DX personnel trained, employee satisfaction +1.0 points.

High evaluation obtained in all four perspectives. And Ibaraki factory's success led to horizontal expansion to other bases.

"Don't judge one-dimensionally. Evaluate multifacetedly through BSC. Financial, customer, business process, learning and growth. When four perspectives align, true overall optimization becomes visible. Balanced strategy achieves reproducible automation."

The next case will also depict the moment of discovering overall optimization from four perspectives.

"BSC—Balanced Scorecard. Evaluate from four perspectives. Financial, customer, business process, learning and growth. Balanced strategy leads to true success"—From the Detective's Notes

Related Files

🎖️ Top 3 Weekly Ranking of Classified Case Files

What is ROI

What is STP Analysis

What is the RICE Framework