ROI Case File No.383 | 'AutomateTech's Darkness of Zero Knowledge'

📅 2026-01-13 23:00

🕒 Reading time: 10 min

🏷️ 6D_MATRIX

- Chapter 1: The Darkness of Zero Knowledge—Don't Even Know Which Tasks to Automate

- Chapter 2: The Illusion of Tool Implementation—WHY Is Not Visible

- Chapter 3: Phase 1—Visualizing Challenges with 6D-MATRIX

- Chapter 4: Phase 2—Ensuring Reproducibility Through Phased Internalization

- Chapter 5: The Detective's Diagnosis—Decompose Challenges from 6 Dimensions

- Related Files

Chapter 1: The Darkness of Zero Knowledge—Don't Even Know Which Tasks to Automate

The day after resolving TransLingua's Blue Ocean incident, a new consultation arrived regarding business automation internalization. Volume 31, "The Pursuit of Reproducibility," Episode 383, tells the story of decomposing challenges from 6 dimensions.

"Detective, we have no knowledge. We want to implement Power Automate. But no one in our company has knowledgeable personnel. We don't know how to use the tool. We don't even know which tasks to automate. We have absolutely no idea where to start."

Tomoko Tanaka, Business Reform Department Manager at AutomateTech Inc. from Shinagawa, visited 221B Baker Street with a bewildered expression. In her hands were materials printed from Microsoft Power Automate's official website, contrasting sharply with a plan titled "RPA Internal Development Plan 2026" full of blanks.

"We're a mid-sized manufacturer. 320 employees. Annual revenue of 8.5 billion yen. Power Automate came up within the department. We want to automate tasks for efficiency. But we're stuck before construction. Because no one in the company has knowledge."

AutomateTech Inc.'s Current Situation: - Established: 1995 (precision equipment manufacturing) - Employees: 320 - Annual Revenue: 8.5 billion yen - Problem: Zero RPA knowledge, unclear automation target tasks, no internalization structure

There was deep frustration in Tanaka's voice.

"Management's directive is clear: 'Don't outsource everything to external vendors. Internalize. Create a structure we can maintain and manage ourselves.' But we have nothing. What is RPA? What is Power Automate? Which tasks can be used for? How do we use it? We understand nothing."

Reality of Zero Knowledge:

Case 1: Tool Understanding - Question: "What is Power Automate?" - Answer: "Microsoft's tool... I think. Automation... it can do that, right?" - Understanding level: 0%

Case 2: Identifying Automation Target Tasks - Question: "Which tasks do you want to automate?" - Answer: "That's what we don't know. Which tasks can be automated..." - Inventory status: Not conducted

Case 3: Internalization Structure - Question: "Who will build and operate?" - Answer: "We don't know that either. We don't have a specialized department, and no staff assigned." - Structure: Zero

Current Problem Chain: 1. No knowledge → Can't use tools 2. Can't use tools → Can't inventory tasks 3. Can't inventory tasks → Can't decide automation targets 4. Can't decide automation targets → Nothing progresses

Tanaka sighed deeply.

"There's another problem. Even when we try to gather information, we don't know what to research. When we search 'Power Automate how to use' on the internet, it's full of technical terms we can't understand. 'Trigger,' 'Action,' 'Flow,' 'Connector.' All meaningless."

Chapter 2: The Illusion of Tool Implementation—WHY Is Not Visible

"Tanaka-san, do you think implementing Power Automate will solve all problems?"

Tanaka showed a puzzled expression at my question.

"Huh, isn't that the case? I thought if we implement an RPA tool, tasks would be automated."

Current Understanding (Tool Implementation Model): - Expectation: Tasks will be automated if tools are implemented - Problem: WHY (why needed) is not visible

I explained the importance of decomposing challenges from 6 dimensions using 6D-MATRIX.

"The problem is thinking 'implementation of tools will solve it.' 6D-MATRIX—6 Dimensional Matrix. By decomposing challenges from 6 dimensions combining 3 time axes of Present-Future-Past and 3 thought axes of WHY-HOW-WHAT, we achieve reproducible internalization."

⬜️ ChatGPT | Concept Catalyst

"Don't solve with tool implementation. Decompose challenges from 6 dimensions with 6D-MATRIX."

🟧 Claude | Story Alchemist

"Challenges are always 'visible parts' and 'invisible parts.' The key is illuminating from 6 dimensions."

🟦 Gemini | Compass of Reason

"Build 6D-MATRIX's 3×3 matrix. Cover challenges with time and thought axes."

The three members began their analysis. Gemini developed "6D-MATRIX" on the whiteboard.

6D-MATRIX Structure:

WHY(Why) HOW(How) WHAT(What)

Past | ? | ? | ? |

Present| ? | ? | ? |

Future | ? | ? | ? |

"Tanaka-san, let's first find challenges from 6 dimensions."

Chapter 3: Phase 1—Visualizing Challenges with 6D-MATRIX

Step 1: Building 6D-MATRIX (2 weeks)

Time Axis × Thought Axis Matrix:

| Time Axis | WHY (Why) | HOW (How) | WHAT (What) |

|---|---|---|---|

| Past | Why couldn't we automate in the past? | What methods did we try in the past? | Which tasks did we target in the past? |

| Present | Why is automation needed now? | What method should we proceed with now? | Which tasks should we target now? |

| Future | Why is internalization needed in the future? | What structure will we operate with in the future? | What state do we aim for in the future? |

Step 2: Analyzing Each Cell (1 week)

[Past × WHY]: Why couldn't we automate in the past?

Survey Results: - 2020: Considered RPA implementation but abandoned due to 8 million yen quote - Reason: "Don't want to depend on external vendors" (management policy) - Result: Left without doing anything

Challenge: - Avoiding external dependence without internalization knowledge led to no progress

[Past × HOW]: What methods did we try in the past?

Survey Results: - 2021: Tried task automation with Excel VBA - Person in charge: 1 person from IT department (self-taught) - Result: Created 5 macros, but all lost when person in charge left

Challenge: - Due to personnel dependency, knowledge was not transferred

[Past × WHAT]: Which tasks did we target in the past?

Survey Results: - Tasks automated with Excel VBA: 1. Monthly sales aggregation (5 hours → 30 minutes) 2. Inventory report creation (3 hours → 20 minutes) 3. Invoice issuance (8 hours → 1 hour) 4. Expense claim checking (4 hours → 40 minutes) 5. Customer list update (2 hours → 15 minutes)

Discovery: - Past success cases existed (total time saved: 80 hours/month) - But all lost when person in charge left

[Present × WHY]: Why is automation needed now?

Survey Results: - Staff shortage: 3 vacancies (can't hire despite recruiting) - Overtime hours: Monthly average 45 hours (barely within legal limit) - Workload increase: Order volume up 120% year-over-year

Challenge: - Can't increase people → automation is the only option

[Present × HOW]: What method should we proceed with now?

Survey Results: - Management policy: "Internalize" - Budget: 3 million yen annually (including external training and tool costs) - Period: April 2026 - March 2027 (1 year)

Challenge: - Budget and period secured, but specific method unclear

[Present × WHAT]: Which tasks should we target now?

Task Inventory Implementation (1 week):

Inventory Target Departments: - Sales Department: 15 people - Manufacturing Department: 120 people - Accounting Department: 8 people - General Affairs Department: 5 people

Inventory Results (Tasks with High RPA Applicability):

| Department | Task Name | Monthly Hours | Routine Level | Priority |

|---|---|---|---|---|

| Sales | Quote creation | 40 hours | High | A |

| Sales | Order data entry | 32 hours | High | A |

| Accounting | Expense claim checking | 28 hours | Medium | B |

| Accounting | Invoice issuance | 24 hours | High | A |

| General Affairs | Attendance data aggregation | 16 hours | High | B |

Total: Identified 140 hours/month of automatable tasks

[Future × WHY]: Why is internalization needed in the future?

Survey Results: - Risks of external vendor dependency: - Costs incurred with each modification (500,000 yen+ per time) - Can't respond immediately to business changes - Vendor withdrawal risk

Challenge: - Without internalization, becomes uncontrollable long-term

[Future × HOW]: What structure will we operate with in the future?

Target Structure: - RPA Team Establishment: 3 dedicated members (1 each from sales, accounting, IT) - Knowledge Standardization: Share through manuals, videos, internal wiki - External Training: Expert guidance once a week for initial 3 months

Challenge: - Need team member selection and development

[Future × WHAT]: What state do we aim for in the future?

Goals (End of March 2027): - Automate 10 tasks (reduce 140 hours/month) - RPA team of 3 can operate independently - Can handle new task automation in-house

KPIs: - Automated tasks: 10+ cases - Time saved: 100+ hours/month - Team self-sufficiency rate: 80%+

Chapter 4: Phase 2—Ensuring Reproducibility Through Phased Internalization

Step 3: Implementation Plan (Months 1-12)

Months 1-3: Basic Learning Phase

External Training (once a week × 12 times): - Weeks 1-2: Power Automate basics (trigger, action, flow) - Weeks 3-4: Practical exercises (simple task automation) - Weeks 5-8: Intermediate techniques (conditional branching, loops, error handling) - Weeks 9-12: Applied exercises (complex task automation)

Self-study (5 hours/week × 12 weeks): - Microsoft official learning path - Udemy video courses - In-house practice assignments

Deliverables: - RPA team of 3 acquires basic knowledge - Automate simple tasks (5 tasks)

Months 4-6: Practical Phase

Target Tasks (Priority A): 1. Quote creation (Sales Department) 2. Order data entry (Sales Department) 3. Invoice issuance (Accounting Department)

Construction Process (2 weeks per task): - Week 1: Task flow analysis + design - Week 2: Construction + testing + production operation

Months 4-6 Results: - Automate 3 tasks - Reduce 96 hours/month (quote 40h + order 32h + invoice 24h)

Months 7-9: Expansion Phase

Target Tasks (Priority B): 4. Expense claim checking (Accounting Department) 5. Attendance data aggregation (General Affairs Department) 6. Inventory report creation (Manufacturing Department) 7. Customer list update (Sales Department)

Months 7-9 Results: - Add 4 task automations - Cumulative 7 tasks, reduce 140 hours/month

Months 10-12: Self-sufficiency Phase

Goal: - Automate new tasks without external support - Standardize knowledge (create manuals, videos)

Target Tasks (RPA team constructs independently): 8. Sales daily report aggregation (Sales Department) 9. Purchase order creation (Manufacturing Department) 10. Payroll data transcription (General Affairs Department)

Months 10-12 Results: - Automate 3 tasks independently - Cumulative 10 tasks, reduce 168 hours/month

Month 12: Effectiveness Measurement

KPI 1: Automated Task Count - Target: 10 tasks - Actual: 10 tasks - Achievement rate: 100%

KPI 2: Time Saved - Target: 100+ hours/month - Actual: 168 hours/month - Achievement rate: 168%

KPI 3: Team Self-sufficiency Rate - Target: 80%+ - Actual: 90% (constructed 3 tasks without external support in Months 10-12) - Achievement rate: 112%

Annual Impact:

Personnel Cost Reduction: - Time saved: 168 hours/month × 12 months = 2,016 hours/year - Hourly rate: 2,800 yen (annual salary 5 million yen ÷ 1,785 hours) - Personnel cost reduction: 2,016 hours × 2,800 yen = 5.64 million yen/year

Investment: - External training cost: 1.2 million yen (12 times × 100,000 yen) - Power Automate licenses: 360,000 yen (3 people × 12 months × 10,000 yen) - Internal work hours (RPA team 3 people's personnel cost): 9 million yen (3 people × 3 million yen) - Total initial investment: 10.56 million yen

ROI: - Year 1: Negative (investment 10.56 million yen - effect 5.64 million yen = -4.92 million yen) - Year 2 onward: 5.64 million yen/year reduction (no training costs, only 360,000 yen license) - Year 2 net effect: 5.28 million yen - Payback period: 10.56 million yen ÷ 5.64 million yen = 1.87 years (about 2 years)

Chapter 5: The Detective's Diagnosis—Decompose Challenges from 6 Dimensions

That night, I reflected on the essence of 6D-MATRIX.

AutomateTech Inc. held the illusion that "implementing tools will solve it." However, if WHY (why needed) is not visible, HOW (how) and WHAT (what) won't be decided either.

Using 6D-MATRIX, we decomposed challenges from 6 dimensions of time axis (Past-Present-Future) and thought axis (WHY-HOW-WHAT). We learned from past failures (Excel VBA personnel dependency), identified present challenges (staff shortage causing 140 hours/month task overload), and defined future ideals (internalization team self-sufficiency rate 90%).

Annual personnel cost reduction of 5.64 million yen, 2-year payback, automation of 10 tasks.

The key is illuminating not just "visible parts" but also "invisible parts." See not just the present but also past and future. Ask not just WHAT but also WHY and HOW. By decomposing challenges from 6 dimensions, reproducible internalization is achieved.

"Don't solve with tool implementation. Decompose challenges from 6 dimensions with 6D-MATRIX. By covering challenges with time and thought axes, true solutions become visible. Reproducible internalization begins with 6-dimensional understanding."

The next case will also depict the moment of decomposing challenges from 6 dimensions.

"6D-MATRIX—6 Dimensional Matrix. Decompose challenges from 6 dimensions of Present-Future-Past and WHY-HOW-WHAT. By illuminating not just visible parts but also invisible parts, reproducible solutions emerge."—From the Detective's Notes

Related Files

🎖️ Top 3 Weekly Ranking of Classified Case Files

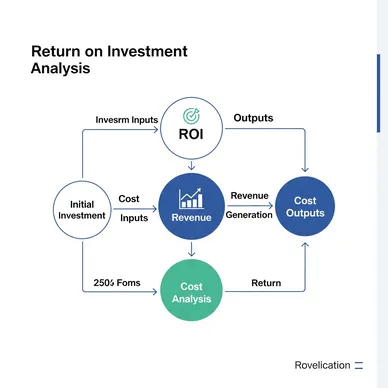

What is ROI

What is Blue Ocean Strategy

What is the ECRS Principle