ROI 【🔏CLASSIFIED CASE FILE】 No. X003 | What is PDCA

📅 2025-05-12

🕒 Reading time: 5 min

🏷️ PDCA 🏷️ Learning 🏷️ 【🔏CLASSIFIED CASE FILE】

- What is PDCA - Case Overview

- Basic Structure of PDCA - Evidence Analysis

- PDCA Implementation Procedure - Investigation Methods

- The Power of PDCA - Hidden Truths

- PDCA Limitations and Precautions - Potential Dangers

- PDCA Variants and Related Methods - Related Case Files

- Conclusion - Investigation Summary

Detective's Note: The four letters "PDCA" witnessed everywhere from posters on conference room walls to the opening of business improvement proposals. The cycle formed by the initials Plan, Do, Check, Action represents an improvement cycle that continues rotating like a perpetual motion machine. However, testimonies suggest that many workplaces claim to "run PDCA" but actually stop at "PD." Determine the true power of this improvement method and why it malfunctions in many organizations.

What is PDCA - Case Overview

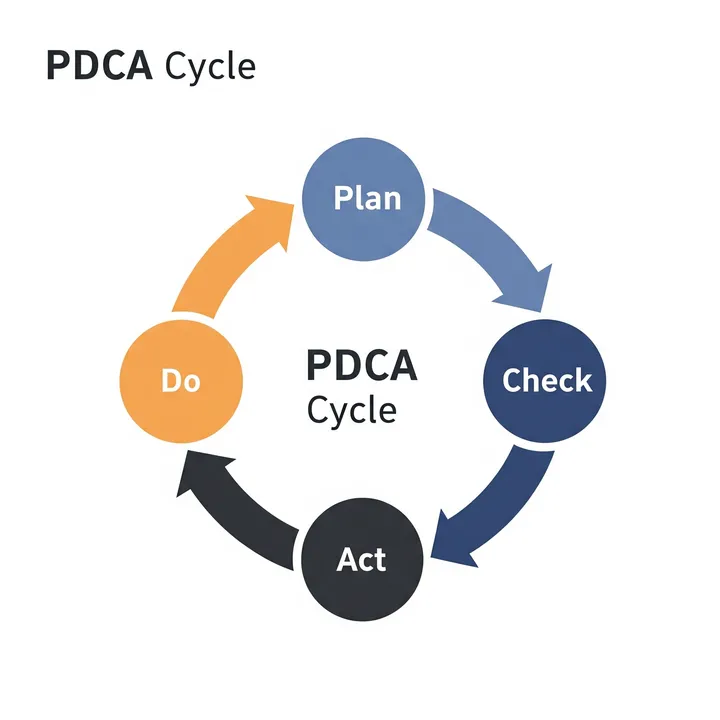

PDCA (Plan-Do-Check-Action), the cycle of "planning-execution-evaluation-improvement." Originating from quality management methods proposed by American statistician Deming in the 1950s, it has now widely spread as a fundamental framework for business improvement. Frequently mentioned among clients as synonymous with "continuous improvement," yet its practice contains many pitfalls.

Investigation Memo: A method that improves quality and efficiency in a spiral pattern by cycling through four steps. Theoretically perfect, but various obstacles occur in actual operation. This mystery needs solving.

Basic Structure of PDCA - Evidence Analysis

Primary Evidence: The Four PDCA Stages

Plan - Goal Setting and Planning

"What, when, and how to improve"

"Current situation analysis and goal setting"

"Formulation of specific action plans"

"Setting success indicators (KPIs)"

Do - Implementation of the Plan

"Execution of actions based on the plan"

"Process recording and progress management"

"Response to unexpected events"

"Collection of execution data"

Check - Verification of Results

"Measurement of goal achievement"

"Reflection on execution processes"

"Analysis of success and failure factors"

"Extraction of lessons for the next cycle"

Action - Standardization and Reflection to Next Cycle

"Standardization of successful initiatives"

"Consideration of improvement measures for problems"

"Reflection to next cycle planning"

"Promotion of organizational learning"

Evidence Analysis: PDCA's excellence lies in its design premised on "continuous improvement" rather than "one-time improvement." Each step becomes the foundation for the next step, creating a mechanism where the entire cycle realizes spiral quality improvement.

PDCA Implementation Procedure - Investigation Methods

Investigation Finding 1: Plan Stage Details

Case Evidence (Sales Department Revenue Improvement Initiative):

Current Situation Analysis:

・Monthly sales target achievement rate: 80%

・Main issue: Insufficient new prospect development

・Root cause: Quality and quantity problems with customer lists

Goal Setting:

・Achieve 95% monthly sales target achievement rate in 3 months

・Increase new prospect development from 20 to 35 cases per month

Action Plan:

・Customer database improvement (Month 1)

・Sales method standardization (Month 2)

・Progress management system strengthening (ongoing)

KPI Setting:

・Approach numbers, deal conversion rate, order rate

・Customer satisfaction, sales activity time allocation

Investigation Finding 2: Do Stage Key Points - Recording learnings during execution process, not just plan execution - Recording responses when unexpected events or issues occur - Collection of both quantitative and qualitative data

Investigation Finding 3: Check Stage Pitfalls - Qualitative evaluation of processes, not just achievement/non-achievement of numerical targets - Identification of success factors (ensuring reproducibility) - Analysis of failure factors (considering avoidance measures)

Investigation Finding 4: Action Stage Essence - Standardization and horizontal deployment of success patterns - Learning from failures and incorporating improvement measures - Concrete handover to the next cycle

The Power of PDCA - Hidden Truths

Critical File 1: Systematic Improvement Approach Rather than ad-hoc improvement activities, realizes highly reliable improvement through systematic processes of plan→execute→evaluate→improve. Enables data-driven improvement without relying on emotions or intuition.

Critical File 2: Promotion of Organizational Learning Builds mechanisms for continuous organizational learning without depending on individual experience or intuition. Failures are also accumulated as learning assets, continuously improving organizational improvement capabilities.

Critical File 3: Culture Development of Continuous Improvement Establishes a culture of "continuously improving" rather than "improvement ends once done" within organizations. Accumulation of small improvements creates significant competitive advantages long-term.

PDCA Limitations and Precautions - Potential Dangers

Warning File 1: "PD" Stopping Syndrome The most frequent problem. Pattern of making plans and executing but neglecting evaluation and improvement. This is merely "execution without follow-up" and doesn't demonstrate PDCA's true value.

Warning File 2: Formalism Trap Cases focusing on arranging PDCA's form while neglecting substantial improvement effects. Only satisfaction of "running PDCA" remains without connecting to actual results.

Warning File 3: Limitations in Speed-Focused Environments In rapidly changing environments, one complete cycle may take too long. In the digital age, distinguishing usage with faster OODA loops (Observe-Orient-Decide-Act) is important.

Warning File 4: Neglect of Check Stage Cases where evaluation (Check) becomes perfunctory due to focus on execution (Do). When falling into "too busy to reflect" situations, learning effects significantly decrease.

Warning File 5: Lack of Specificity in Action Stage Cases remaining at abstract improvement measures like "be more careful next time" or "try harder" without breaking down into concrete actions. This doesn't contribute to the next Plan.

PDCA Variants and Related Methods - Related Case Files

Related Evidence 1: PDSA (Plan-Do-Study-Act)

Improved version later proposed by Dr. Deming

Change from Check → Study

Conceptual shift from "confirmation" to "learning"

Related Evidence 2: OODA (Observe-Orient-Decide-Act)

High-speed decision-making cycle born from military strategy

Observe→Orient→Decide→Act

Suitable for rapid response in VUCA environments

Related Evidence 3: DMAIC (Define-Measure-Analyze-Improve-Control)

Improvement method used in Six Sigma

Define→Measure→Analyze→Improve→Control

Includes more detailed analysis processes

Related Evidence 4: Integration with Scrum Development

Sprint = PDCA cycle

Daily standup = small Check

Retrospective = Check + Action

Conclusion - Investigation Summary

Detective's Final Report:

PDCA is "the royal road of continuous improvement," with influence extending broadly from manufacturing to service industries and even personal self-improvement. Deep mechanisms for continuously growing organizations are built into the simple structure of four-step circulation.

The most important discovery in this investigation was that most PDCA failures stem from "neglect of C (Check) and A (Action)." While planning and execution are relatively easy, objective evaluation and formulation of concrete improvement measures determine this method's true value. "Running PDCA" means equally emphasizing all four steps.

It also became clear that PDCA is not a "universal improvement method." In rapidly changing environments, distinguishing usage with faster OODA loops is necessary, and for creative problem-solving, more flexible approaches may be required.

However, few methods surpass PDCA in establishing a "culture of continuous improvement" within organizations. The accumulation of small improvements eventually creates major transformations. This is PDCA's true power.

Continuous Improvement Maxim: "An imperfect but continuously running cycle produces far greater results than a perfect plan."

Case Closed