ROI 【🔏CLASSIFIED CASE FILE】 No. X005 | What is 5 Whys

📅 2025-05-16

🕒 Reading time: 6 min

🏷️ 5Whys 🏷️ Learning 🏷️ 【🔏CLASSIFIED CASE FILE】

- What is 5 Whys - Case Overview

- Basic Structure of 5 Whys - Evidence Analysis

- 5 Whys Implementation Procedure - Investigation Methods

- The Power of 5 Whys - Hidden Truths

- 5 Whys Limitations and Precautions - Potential Dangers

- 5 Whys Variants and Related Methods - Related Case Files

- Conclusion - Investigation Summary

Detective's Note: A method called "5 Whys" frequently witnessed in problem-solving scenes. Reportedly, asking just one question "Why?" five times can reach the root cause of problems. This method, systematized by Taiichi Ohno, father of the Toyota Production System, is widely utilized from manufacturing to service industries and even personal problem-solving. However, reports continue that many workplaces remain at superficial understanding of "just ask why five times" and cannot demonstrate its true power. Determine the identity of this simple yet profound analytical method.

What is 5 Whys - Case Overview

5 Whys, also called "Why-Why Analysis," is a root cause analysis method. It systematically deep-dives from superficial causes to true root causes by repeatedly asking "Why?" to problems. Born at Toyota Motor in the 1930s, it's now widely utilized from manufacturing quality control to IT industry failure analysis and even personal behavior improvement. Among our clients, it's recognized as "a method for exploring problem roots," yet its practice requires more technique and insight than imagined.

Investigation Memo: Within the simple structure of repeating "Why?" five times lies the power to expose human thinking habits and organizational structural problems. We need to clarify why "five times" and why this is so effective.

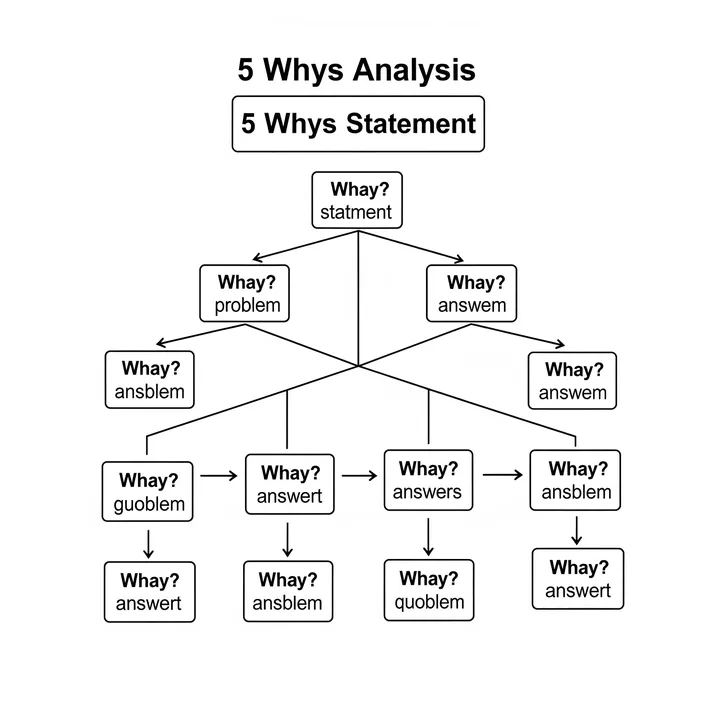

Basic Structure of 5 Whys - Evidence Analysis

Primary Evidence: Systematic Deep-dive of 5 Whys

Stage 1: Problem Phenomenon Understanding

"What happened?" (fact confirmation)

"When, where, to whom did it happen?"

"What degree of impact occurred?"

Stages 2-6: Systematic Cause Analysis

Why 1: Why did that problem occur?

Why 2: Why did that cause arise?

Why 3: Why did such a situation develop?

Why 4: Why does that system/mechanism exist?

Why 5: Why does that fundamental structure exist?

Evidence Analysis: 5 Whys' excellence lies in enabling root cause identification that leads to fundamental structural reform rather than superficial symptomatic treatment. While many problem-solving efforts end with "treating symptoms," this method enables "removing the root."

5 Whys Implementation Procedure - Investigation Methods

Investigation Finding 1: Concrete Implementation Example (Manufacturing Defect Occurrence)

Case Evidence:

Problem: Product scratches occurred causing defects

Why 1: Why did scratches appear on the product?

→ Because machine parts contacted the product

Why 2: Why did machine parts contact the product?

→ Because part positions were misaligned

Why 3: Why were part positions misaligned?

→ Because fixing bolts were loose

Why 4: Why were fixing bolts loose?

→ Because periodic inspections weren't performed

Why 5: Why weren't periodic inspections performed?

→ Because inspection schedules weren't clear and no responsible party was designated

Root Cause: Inadequate maintenance management system

Countermeasure: Establish inspection schedules and clarify responsible parties

Investigation Finding 2: Service Industry Application Example (Customer Complaint Response)

Case Evidence:

Problem: Customer complained about "slow response"

Why 1: Why was response called slow?

→ Because it took 3 days from inquiry to answer

Why 2: Why did it take 3 days?

→ Because the assignee was absent and the substitute couldn't grasp the situation

Why 3: Why couldn't the substitute grasp the situation?

→ Because customer information sharing systems weren't established

Why 4: Why weren't sharing systems established?

→ Because each assignee managed individually with Excel

Why 5: Why was management individualized?

→ Because company-wide information management rules didn't exist

Root Cause: Lack of organizational information management system

Countermeasure: CRM system implementation and operational rule establishment

Investigation Finding 3: Important Implementation Points - Fact-based analysis (eliminate speculation and assumptions) - View as system/mechanism problems, not blaming individuals - When multiple causes exist at each stage, select the most impactful one - Consider concrete countermeasures once root cause is reached

The Power of 5 Whys - Hidden Truths

Critical File 1: Escape from Symptomatic Treatment While many problem-solving efforts end with superficial symptom treatment, 5 Whys forces reaching root causes. Demonstrates tremendous effectiveness in preventing problem recurrence.

Critical File 2: Promotion of Organizational Learning By reframing problems that tend to be processed as individual mistakes into system and mechanism issues, it leads to organization-wide improvement. Guides toward constructive improvement rather than personal attacks.

Critical File 3: Thought Structuring Converts emotional problem analysis into logical, systematic thinking. Promotes conceptual shift from "who's at fault" to "what's the cause."

Critical File 4: Achievement of Essential Improvement By reaching fundamental mechanism improvements rather than superficial countermeasures, it derives improvement measures with high investment effectiveness.

5 Whys Limitations and Precautions - Potential Dangers

Warning File 1: Linear Thinking Trap Complex problems often have multiple causes, but 5 Whys tends toward single-track analysis. Risk of overlooking important causes exists.

Warning File 2: Subjective Judgment Intrusion Danger that responses to "Why?" are influenced by analyst subjectivity and experience. Objective data and factual backing are essential.

Warning File 3: "Five Times" Fixed Mindset Misconception that it must be exactly five times. Actually, root causes may be reached in three iterations or require 7-8 iterations.

Warning File 4: Transformation into Personal Attacks Cases where insufficient practitioner skills lead to individual responsibility pursuit rather than system problems. Risk of triggering organizational defensive reactions.

Warning File 5: Analysis Fatigue State where substantial insights aren't gained by merely repeating "Why?" formally. Risk of falling into analysis for analysis' sake.

5 Whys Variants and Related Methods - Related Case Files

Related Evidence 1: Why Tree

Parallel development of multiple "Whys" for one problem

Visualizing complex cause structures

Effective when combined with fishbone diagrams

Related Evidence 2: How-How Analysis

Reverse pattern of 5 Whys

Concretizing solutions by repeating "How?"

Flow from Why (cause analysis) → How (solution planning)

Related Evidence 3: RCA (Root Cause Analysis)

More systematic root cause analysis method

Combining multiple analytical techniques including 5 Whys

Operating as organizational problem-solving process

Related Evidence 4: A3 Thinking (Toyota Problem-Solving)

Consolidating problem-solving process on one A3 sheet

Visualizing cycle of current situation understanding → 5 Whys → countermeasure planning → effect verification

Related Evidence 5: FMEA (Failure Mode and Effects Analysis)

Preventive problem analysis method

Analyzing "why failures occur" in advance

Powerful preventive effects when combined with 5 Whys

Conclusion - Investigation Summary

Detective's Final Report:

5 Whys is "a sharp blade for problem-solving." Despite being a simple method of merely repeating one question "Why?", its power is tremendous. It possesses a structure that forces reaching root causes against many problem-solving efforts that tend to end with superficial symptomatic treatment.

The most impressive finding in this investigation was that 5 Whys is not merely an analytical method but possesses "the power to transform organizational thinking culture." The conceptual shift from "who's at fault" to "what's the cause," the directional change from personal attacks to constructive improvement - these significantly improve organizational maturity.

However, the "dangers" of this method also became apparent. Depending on analyst skills and attitudes, it can become a tool for personal attacks or end in formal analysis. To demonstrate true power, fact-based objective analysis and awareness toward structural improvement through systems thinking are essential.

Additionally, 5 Whys is not a "universal analytical method." Complex problems require combination with other methods, and from a preventive perspective, methods like FMEA may be effective. Appropriate method selection creates true problem-solving capability.

Root Cause Analysis Maxim: "True problem-solving means never allowing the same problem to occur twice."

Case Closed

Solve Your Business Challenges with Kindle Unlimited!

Access millions of books with unlimited reading.

Read the latest from ROI Detective Agency now!

*Free trial available for eligible customers only