ROI事件ファイル No.311|『NeoFab社の見えない判断』

📅 2025-11-11 23:00

🕒 読了時間: 16 分

🏷️ OODA

第一章:ベテランという城壁——判断が一人に集中する工場

AutoForgeのダブルダイヤモンド事件が解決した翌週、今度は茨城から精密機械部品メーカーのAI導入に関する相談が届いた。第二十六巻「再現性の追求」の幕開けとなる第311話は、ベテランの判断を誰もが再現できる仕組みに変える物語である。

「探偵、我々の製造ラインは一人のベテランに依存しています。彼がいなければ、不良品への対応が遅れます。若手は判断できず、ラインを止めてベテランを呼びます。その間、生産が止まります。もう、限界です」

NeoFab Manufacturing社 の生産管理部長、つくば出身の田村浩二は疲弊しきった表情でベイカー街221Bを訪れた。彼の手には、ベテラン社員の勤務表と、それとは対照的に「判断遅延」と記された生産停止記録が握られていた。

「我々は茨城で精密機械部品を製造しています。自動車、航空機、産業機械向けの部品です。製造ラインは3ライン。作業員は45名。しかし、不良品への対応は一人のベテラン、木村に頼りきりです」

NeoFab社の現場判断停滞: - 設立:1992年(精密機械部品製造) - 年間売上:28億円 - 従業員数:52名(うち製造45名) - 製造ライン:3ライン(24時間稼働) - ベテラン判断者:木村(58歳、勤続32年) - 不良発生時の初動:木村到着まで平均18分 - 月間生産停止時間:累計42時間(判断待ち) - 問題:木村不在時、若手は判断できず生産停止

田村の声には深い危機感があった。

「木村は来年定年です。彼の判断力を若手に引き継ぎたい。でも、彼の判断は『経験と勘』です。言語化できません。マニュアルを作ろうとしましたが、『ケースバイケース』としか言えないのです」

典型的な不良発生時の対応:

午前2時、Aライン: センサーアラーム:「製品寸法が規格外」

若手作業員(24歳): 「まずい、不良品が出た。でも、どう対応すればいいか分からない……木村さんを呼ばないと」

電話: 「木村さん、Aラインで寸法異常です。来てください」

木村(自宅から車で20分): 「分かった。すぐ行く。それまでラインを止めておけ」

20分後、木村到着: 木村は製品を手に取り、目視で確認。さらに、金型の温度、材料のロット番号、前工程の記録を確認した。

「ああ、これは金型の摩耗だな。Cパターンの摩耗。交換時期が近づいている。とりあえず、金型の温度を3度下げれば、あと2時間は持つ。その間に交換準備をしろ」

設定変更完了、ライン再開: 停止時間:25分

若手作業員は呆然とした。

「木村さんはどうやって判断したんですか?」

「経験だよ。金型の摩耗パターンは3種類ある。音、製品の表面、寸法の出方で分かる。30年やってりゃ、見れば分かる」

「マニュアルにできませんか?」

「難しいな。ケースが多すぎる」

第二章:経験という牢獄——再現できない知見は資産ではない

「田村さん、木村さんの判断を再現するために、どのような取り組みをされてきたのでしょうか?」

私の問いに、田村は答えた。

「マニュアル化を試みました。しかし、木村の判断は複雑すぎて、文書にできません。『この場合はA、あの場合はB』と書こうとしても、『場合』が何百通りもあります。結局、『木村に聞け』となってしまいます」

現在のアプローチ(属人化型): - 対応:木村の判断に依存 - 引き継ぎ:マニュアル化を試みるも失敗 - 問題:木村の不在時、若手は判断できない

私は即応判断の仕組み化の重要性を説いた。

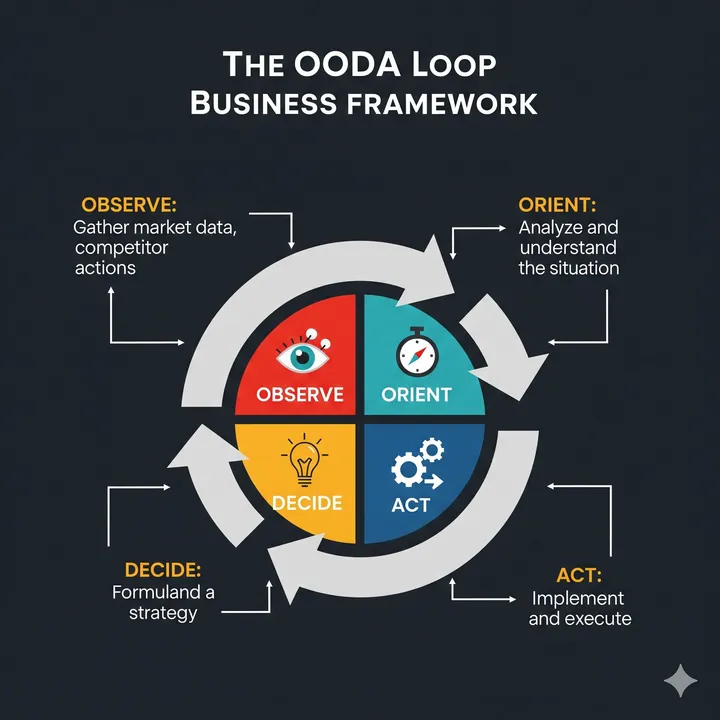

「木村さんの経験は貴重です。しかし、それが一人に閉じている限り、組織の資産にはなりません。OODA——観察し、判断し、決断し、行動する。このループをAIで支援すれば、木村さんの判断を誰もが再現できます」

⬜️ ChatGPT|構想の触媒

「経験を閉じ込めるな。OODAでベテランの判断を全員の武器に変えろ」

🟧 Claude|物語の錬金術師

「AIは人を置き換えない。30年の経験を、3分で使える形に変えるのだ」

🟦 Gemini|理性の羅針盤

「OODAは即応の技術。観察・判断・決断・行動を高速化し、現場に決定権を返せ」

3人のメンバーが分析を開始した。Geminiがホワイトボードに「OODA × AIのフレームワーク」を展開した。

OODAループのAI支援設計: 1. Observe(観察):センサー・カメラでリアルタイムデータ収集 2. Orient(状況判断):AIが異常パターンを即座に分類 3. Decide(決断):現場作業員がAI提案を元に判断 4. Act(行動):対応を実行し、結果を学習に反映

「田村さん、NeoFabの現場判断を、OODAとAIで再構築しましょう」

第三章:観察の眼——30年の経験をデータに変える

Phase 1:Observe(観察) - データ収集基盤の構築(6週間)

まず、木村の判断プロセスを徹底的に観察し、データ化した。

木村の判断に使われる情報: - 製品寸法(マイクロメーター測定) - 金型温度(温度センサー) - 材料ロット番号(記録) - 前工程の加工時間(記録) - 製品の表面状態(目視) - 機械の音(聴覚)

これらをセンサー・カメラで自動収集: - 製品寸法:非接触センサーで連続測定 - 金型温度:IoT温度センサー(10秒ごと) - 表面状態:高解像度カメラ(1個ごと撮影) - 機械の音:音響センサー(周波数分析) - 投資:センサー・カメラ設置費用1,200万円

6週間後: 3ラインに計48個のセンサー・カメラを設置完了

Phase 2:Orient(状況判断) - AIモデルの構築(3ヶ月)

次に、木村の過去の判断データを学習させた。

学習データの収集(過去2年分): - 不良発生記録:820件 - 各記録に紐づくデータ: - センサー値(寸法、温度、音) - 画像(製品表面) - 木村の判断内容(対処方法) - 対処後の結果(成功/失敗)

AIモデルの設計: - 不良パターンを分類(15パターン) - 金型摩耗(Cパターン) - 材料不良(硬度異常) - 温度異常(冷却不足) - ... 等 - 各パターンに対する推奨対処方法を提示 - 信頼度スコアも表示(「80%の確率でCパターン摩耗」)

3ヶ月後: AIモデル完成。テストでは過去データの90%を正確に分類

Phase 3:Decide(決断) - 現場作業員への権限移譲(2ヶ月)

AIモデルを現場に導入し、若手作業員が判断できる体制を構築した。

新しい不良対応フロー:

午前2時、Aライン: センサーアラーム:「製品寸法が規格外」

若手作業員: タブレットを開く。AIが即座に分析結果を表示。

【AI判断結果】

不良パターン: 金型摩耗(Cパターン)

信頼度: 85%

推奨対処:

1. 金型温度を3度下げる

2. あと2時間で金型交換準備

3. 交換後、温度設定を元に戻す

過去の成功率: 92%

若手作業員: 「なるほど、金型の温度を下げればいいのか。やってみよう」

設定変更完了、ライン再開: 停止時間:5分(従来の25分から80%削減)

木村への連絡は不要

Phase 4:Act(行動) - 学習ループの構築(継続)

対応結果をAIに学習させ、判断精度を日々向上させた。

学習の仕組み: - 作業員がAI提案に従って対応 - 対応結果(成功/失敗)を記録 - AIが結果を学習し、次回の判断に反映 - 週次でモデルを更新

3ヶ月後: - AI判断精度:90% → 94% - 木村の判断精度:96%(わずか2%の差まで接近)

第四章:解放という成果——ベテランは教師から監督者へ

6ヶ月後の成果:

生産停止時間の劇的削減: - 月間生産停止時間:42時間 → 8時間(81%削減) - 1件あたりの対応時間:平均18分 → 平均4分(78%削減)

若手の判断力向上: - AI支援により、若手が85%のケースで自己判断可能に - 木村への依存度:100% → 15%(複雑なケースのみ)

木村の役割変化:

Before: 「私がいないと、工場が回らない。夜中も呼び出される。疲れた」

After: 「若手がAIを使って自分で判断できるようになった。私は複雑なケースだけをサポートすればいい。そして、AIの判断を見ながら、『なるほど、こういうパターンもあったな』と気づくこともある。AIが私の教師になっている」

組織の変化: - 木村の定年後も、判断ノウハウが組織に残る - 若手の成長速度が加速(AI支援で経験を積める) - 24時間稼働体制が安定(誰でも対応可能)

12ヶ月後の事業成果:

生産性向上: - 稼働率:82% → 93%(生産停止時間削減の効果) - 年間生産量:+11%

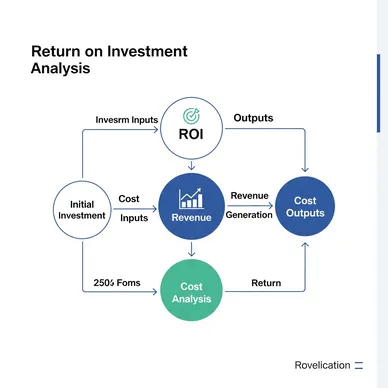

財務効果: - 投資:1,200万円(センサー・AI開発) - 生産増加による売上増:年間3億円 - 投資回収期間:4.8ヶ月

顧客からの評価: 「NeoFab社は納期遵守率が向上しました。以前は不良対応で遅延することがありましたが、今はほとんどありません」

第五章:探偵の診断——第二十六巻「再現性の追求」開幕

その夜、OODAとAIの本質について考察した。

NeoFabは一人のベテランに依存していた。木村の30年の経験は貴重だが、それが一人に閉じている限り、組織の資産ではなかった。

しかし、OODAループをAIで支援することで、木村の判断を誰もが使える形に変えた。観察をセンサーが行い、判断をAIが提示し、決断を若手が行う。

「AIは人を置き換えない。経験を民主化する。ベテランの知見を、全員が使える武器に変えるのだ」

第二十六巻「再現性の追求」、ここに開幕。

次なる事件もまた、OODAが現場の即応力を生む瞬間を描くことになるだろう。

「経験を一人に閉じ込めるな。OODAとAIで、ベテランの判断を全員の武器に変えよ。即応とは、誰もが決断できることだ」——探偵の手記より

関連ファイル

🎖️ Top 3 Weekly Ranking of Classified Case Files

ROIとは何か

STP分析とは何か

RICEフレームワークとは何か